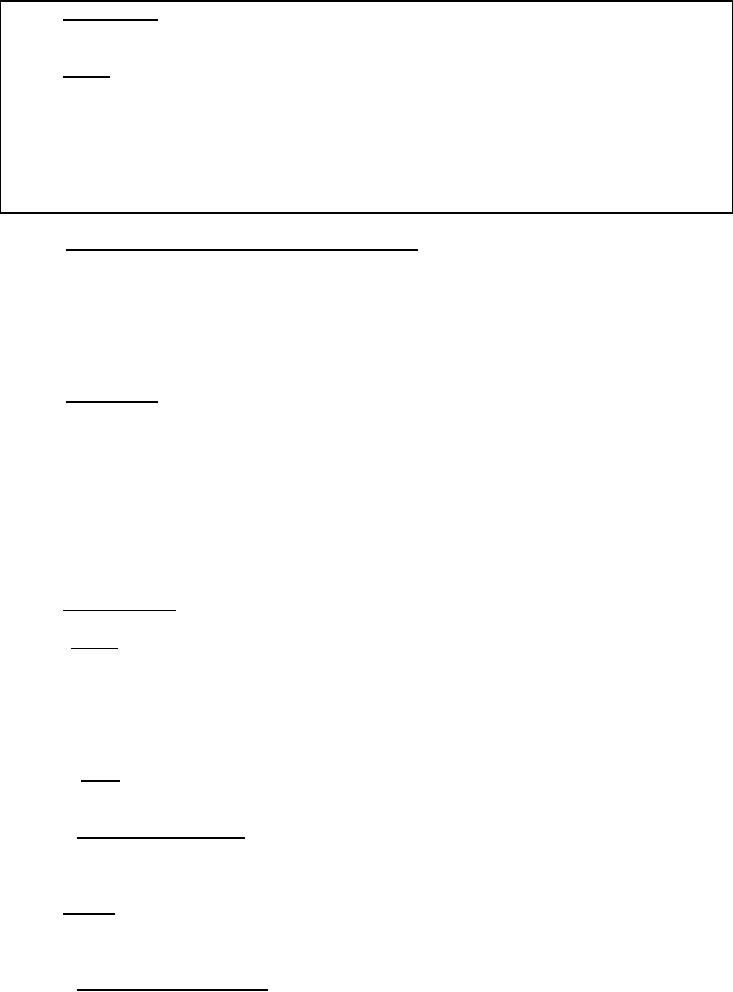

MIL-DTL-43455K

Hand washing: Wash in warm water using mild detergent. DO NOT WRING OR TWIST. Rinse

11.

in clean warm water.

12.

DO NOT USE CHLORINE BLEACH OR STARCH.

Drying: Dry at low heat (do not exceed 130oF). After drying, tumble at room temperature for 10

13.

minutes. Remove immediately from dryer. To drip dry, remove from water and place on a rustproof

hanger.

14.

Pressing is acceptable provided the front flap of the coat overlaps the slide fastener and the

temperature of the steam press does not exceed 300oF when using a hand iron. Do not iron over collar slide

fastener.

DO NOT REMOVE THIS LABEL

3.3.9.3 Combination size, identification and instruction label. The identification label, size label and

instruction label may be combined into one label, conforming to class 14. The three labels shall be printed

as one continuous label with the size label first and the identification and instruction labels placed below the

size label. The size and identification labels may be combined and the contents placed above the instruction

label. A space of 1/2 inch minimum shall be maintained between the labels. In addition a solid line 1/16

inch minimum width shall extend across the entire label approximately in the middle of the 1/2 inch blank

space.

3.3.9.4 Barcode label. Each coat shall be individually bar coded with a paper tag for personal clothing

items. The paper tag shall be standard bleached sulfate having a basis weight of 100 pounds. The paper

used for the tags shall have a smooth finish to accept thermal transfer and direct printing. The tags shall

have a hole and shall be attached to each coat by a fastener. The tags shall be clearly legible and readable

by scanner. The bar coding element shall be a 13 digit national stock number (NSN). There shall be a 12

digit UPC number assigned for all NSNs by the contracting activity. The initials "UPC" must appear

beneath the code. The bar code for NSN and UPC type shall be a medium to high density and shall be

located so that it is completely visible on the coat when it is folded and/or packaged as specified and so it

causes no damage to the coat. The UPC code must also be placed on all shipping cartons on which the

NSN appears.

3.3.10 Thread and gimp.

3.3.10.1 Thread. The thread shall be cotton-covered or polyester-covered polyester core

thread conforming to A-A-50199, ticket numbers 30, 2 or 3 ply and 50, 2 ply for all seaming, stitching,

buttonholes and button sewing and ticket number 70, 2 ply for overedging. As an alternate, either type IV

or V, class 1, subclass B of MIL-DTL-32072 may be used. Tex size 40 shall be used in lieu of ticket

numbers 50 and 70 and Tex size 60 shall be used in lieu of ticket number 30. The thread shall be water

repellent treated in accordance with type II, class 3 of MIL-T-3530.

3.3.10.2 Gimp. The cotton gimp for reinforcing buttonholes shall conform to type I or type II,

ticket number 8 of A-A-50198.

3.3.10.3 Color of thread and gimp. The thread and gimp for classes 1 and 2 shall be dyed

Camouflage Green 483, approximating color chip 34094 of FED-STD-595, for class 4 shall be Khaki P-1,

C.A. 66019 and for class 5 shall be Foliage Green 504.

3.3.11 Buttons. The buttons shall be 30-line, 4-hole, conforming to type II, class D, style 26 of V-B-871.

The color of the buttons for classes 1 and 2 shall be Olive Green BP, for class 4 shall be Tan AJ Cable

62028 and for class 5 shall be Foliage Green 504. The finish shall be dull.

3.3.12

Fasteners, slide, interlocking. The slide fasteners shall be fabricated in conformance

to A-A-55634.

7

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business