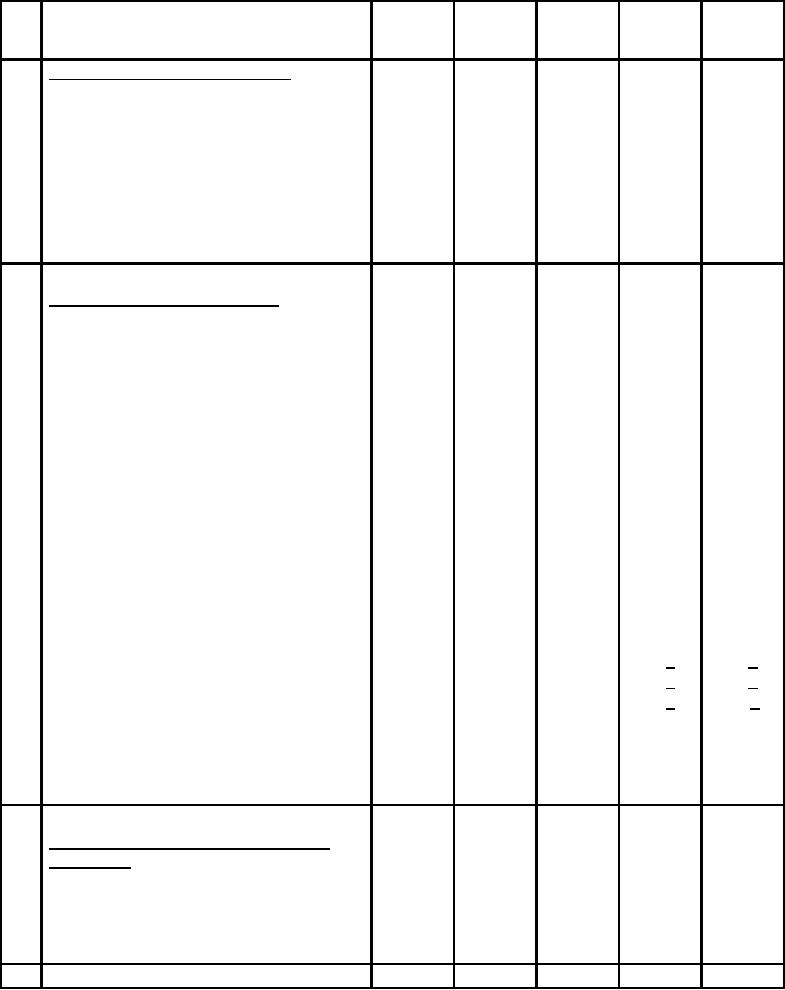

MIL-DTL-43455K

Seam and

Stitches Per

Thread

Thread

Stitch Type Stitching

No.

Manufacturing Operations Requirements

Inch

Needle

Bobbin/

Type

14

Join side and shoulder seams of coat. (Cont'd)

c. Bartack lower end of bi-swing at side seam

28 per

with a vertical 1/2 inch bartack superimposed

Bartack

30

30

on inner row of side seam stitching (double

bartack

stitched seam), or the raise stitching.

d. Position the shoulder loops on shoulder

with back edge of loop 3/4 to 1 inch back from

301

SSa-1

8-14

30

30

shoulder seam and stitch raw edge of loop to

edge of armhole.

15

Attach waist tunnel for drawcords.

Finished appearance. The drawcord shall not

LSd-1

be caught in the tunnel stitching. The distance

301

8-14

30

30

between the two rows of stitching shall be 7/8

each edge

to 1 inch.

a. Turn in top, bottom, and ends of the tunnel

strip and stitch top and bottom of strip to inside

of coat positioned as indicated on pattern, 1/16

to 1/8 inch from turned edges with drawcord

inserted, catching the turn-in at end of strip in

301

EFa-1

10-14

30

30

the stitching and the top of hanging pockets in

the bottom row of tunnel stitching. Ends of

tunnel strip may be prehemmed prior

toattaching tunnel strip. The drawcord may be

inserted into tunnel after strip has been

attached to coat.

or

502 or

EFd-1

6-8

50 1/

50 1/

b. In lieu of turning in the top and bottom raw

503 and

EFd-1

6-8

50 1/

50 1/

edges, overedge stitch top and bottom edges,

301

LSbj-1

10-14

50 1/

50 1/

sides of the tunnel strip, and stitch to coat.

each edge

c. Knot ends of drawcord.

1/ or 40 conforming to type IV or V, class 1,

subclass B of V-T-285.

Placement of loop tape for name and U.S.

16

Army tapes.

Position the loop portion of the nylon

fastener tape (see operation 1.g) for the name

301

LSbj-1

10-14

30

30

and U.S. Army tapes directly above the right

and left chest pockets, as indicated on pattern.

23

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business