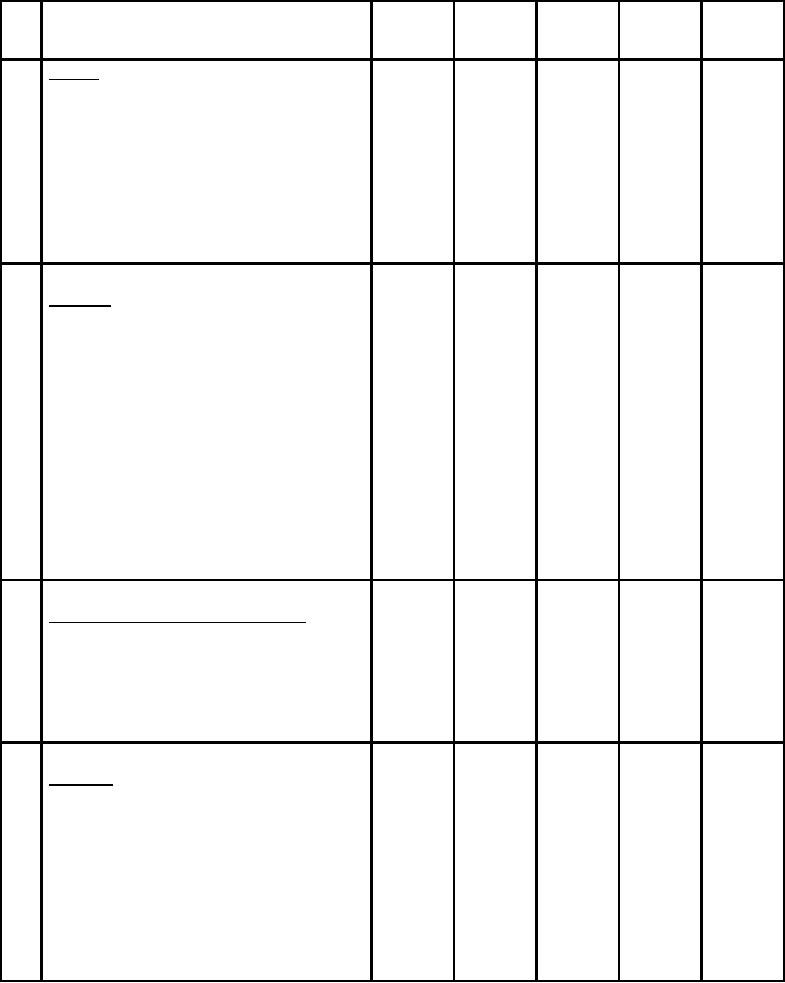

MIL-DTL-43455K

Seam and

Stitches Per

Thread

Thread

Stitch Type Stitching

No.

Manufacturing Operations Requirements

Inch

Needle

Bobbin/

Type

1

Cutting. (cont'd)

k. Cut the reinforcement pieces for

buttonholes and eyelets (where specified) from

one ply of basic material or buckram, or two

plies of the cotton oxford cloth.

l. Cut cotton-nylon sateen cloth (basic

material) for class 1 coat with dull side (filling

effect) of the fabric to finish on the outside of

the garment.

2

Marking.

a. Mark, ticket or bundle all outside parts of

the coat and hood to insure a uniform shade or

shades and size, except those cut from ends

(see operation 1.b). Mark, ticket or bundle all

lining parts for uniformity of size.

b. Any method of marking may be used

except:

(1) Metal fastening devices.

(2) Sew on tickets.

(3) Adhesive type tickets which leave traces

of adhesive on the material after removal of the

tickets.

3

Replacement of defective components.

During the spreading, cutting and

manufacturing process, components having

material defects or damages that are classified

as defects in 4.4.3 shall be removed from

production and replaced with non-defective

and properly matched components.

4

Labeling.

Stitch labels on all four sides to the lining of

coat as follows:

a. Instruction label to the right front and

toward the bottom, 3 to 4 inches back of the

facing.

b. Combination identification-size label to the

back of lining (off-center), 1-1/2 to 2 inches

down from the collar seam. Stitching shall not

catch or restrict the back pleat.

14

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business