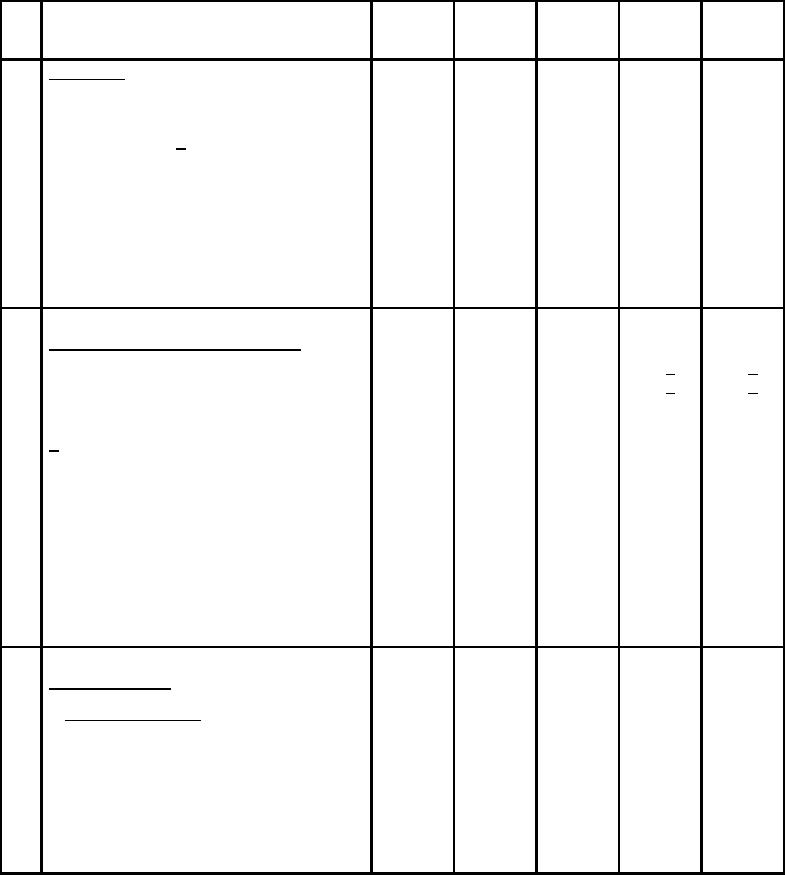

MIL-DTL-43455K

Seam and

Stitches Per

Thread

Thread

Stitch Type Stitching

No.

Manufacturing Operations Requirements

Inch

Needle

Bobbin/

Type

7

Make hood. (Cont'd)

o. Form pleats with outside folded edges

toward the center seam of hood and prestitch

across pleats 3-7/8 + 1/8 inches from bottom

301

10-14

30

30

edge. Stitching may extend across entire width

of hood. (This operation may be performed

when hood curtain is attached to hood.)

p. Thread drawcord through eyelets and knot

ends of drawcord.

1/ or 40 conforming to type IV or V, class 1,

subclass B of V-T-285.

8

Make hood curtain and stitch to hood.

502 or

EFd-1

6-8

70 1/

70 1/

a. Overedge stitch around all raw edges of

70 1/

70 1/

hood curtain.

503

EFd-1

6-8

b. Overlap the top edge of hood curtain 3-7/8

+ 1/8 inches over the bottom edge of hood on

inside and stitch hood curtain to hood 1/8 to

3/16 inch from edge beginning at back edge of

301

LSa-1

10-14

30

30

tunnel strip. The ends of the curtain shall

begin and finish at the back edges of hood

tunnel strip. The pleats of the hood shall be

formed and caught in the stitching if not

previously accomplished in operation 7.o.

1/ or 40 conforming to type IV or V, class 1,

subclass B of V-T-285.

9

Make undercollar.

Finished appearance. The undercollar shall

be interlined with buckram or alternate fusible

and shall contain a slide fastener which shall

finish flat and smooth without puckers. Slide

of fastener shall finish on left side of collar (as

worn) when fastener is closed.

a. Mark undercollar for slide fastener at

marks indicated on patterns.

17

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business