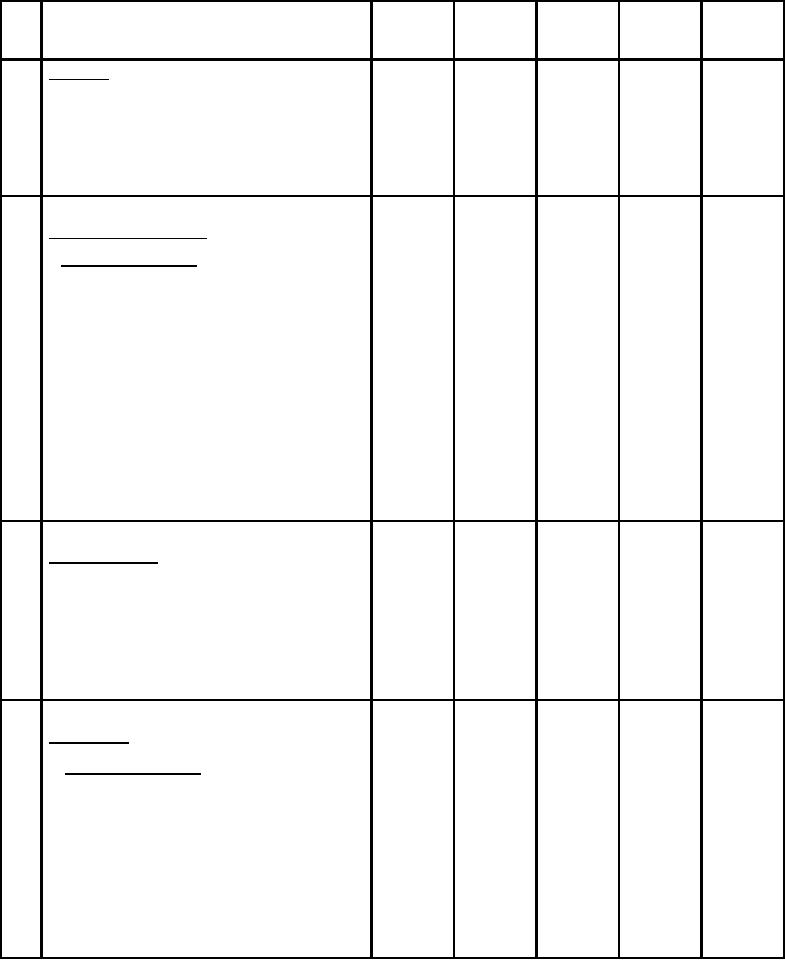

MIL-DTL-43455K

Seam and

Stitches Per

Thread

Thread

Stitch Type Stitching

No.

Manufacturing Operations Requirements

Inch

Needle

Bobbin/

Type

4

Labeling. (Cont'd)

c. Combination size, identification and

instruction label (when used) to be positioned

as specified in operation 4.b.

d. The ends of label stitching shall be

overlapped not less than three stitches.

5

Make four pocket flaps.

Finished appearance. Sockets shall be

reinforced with one ply of buckram or basic

material or two plies of the cotton oxford cloth

cut not less than 1 inch by 1 inch.

a. Mark the position for socket of snap

fastener on flap lining, as indicated by pattern,

and clinch socket to lining of flap and

reinforcement piece. A 1/4 inch off center

tolerance is permitted.

b. Join plies of each flap along side and

301 or

SSe-2(a)

8-14

30

30

bottom edges; turn, work out points and edges,

401 and

SSe-2(a)

8-14

30

50

and stitch flap 3/16 to 1/4 inch from side and

301

SSe-2(b)

10-14

30

30

bottom edges.

6

Make collar tab.

Fold loop portion of nylon fastener tape (see

301

BSa-1

10-14

30

30

operation 1.g) in half lengthwise; insert one

and

end of the cotton tape (see operation 1.j) into

301

OSf-1

10-14

30

30

the full depth of the fold and stitch loop tape to

cotton tape on three sides 1/16 to 1/8 inch from

edges. The stitching may continue across the

folded edge.

7

Make hood.

Finished appearance. The hood shall have

four pleats on back neck and two darts at top.

The eyelets for drawcord shall be securely

clinched through the reinforcement piece and

hood. The drawcord shall not be caught in the

stitching of the tunnel.

a. Place raw edges of darts together and stitch

301 or

SSae-2(a)

10-14

30

30

on outside of hood, 3/16 to 1/4 inch from raw

401

SSae-2(a)

10-14

30

50

edges, with stitch tapering to bottom end of

dart.

15

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business