MIL-DTL-43455K

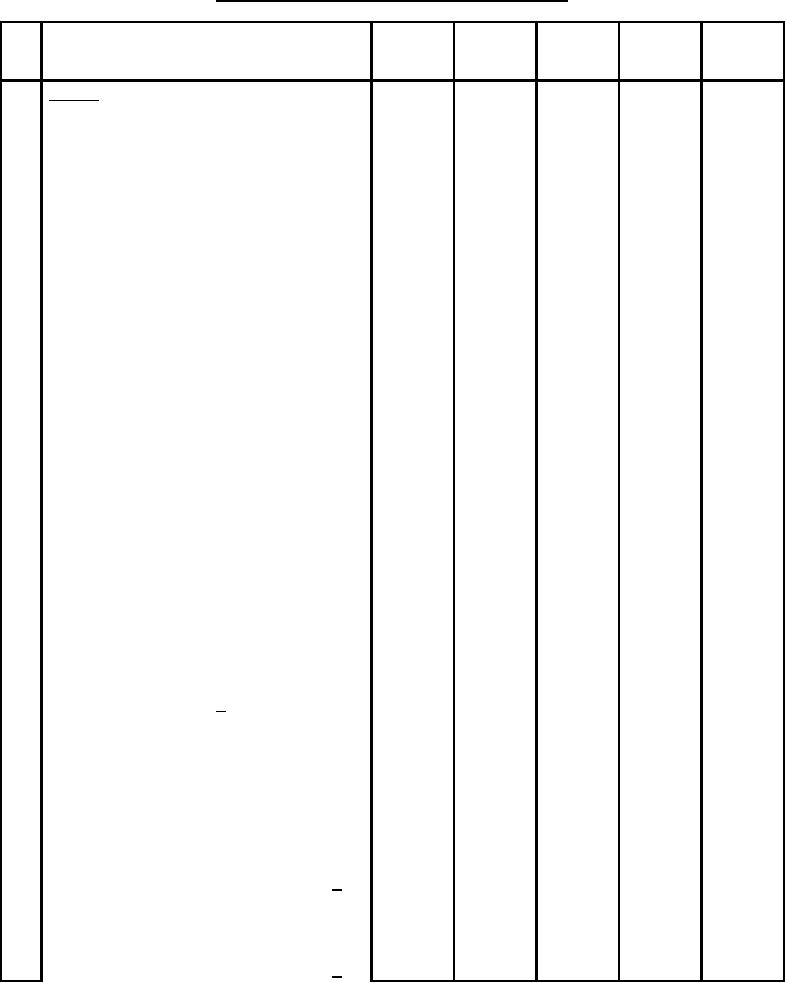

TABLE II. Manufacturing Operations Requirements

Seam and

Stitches Per

Thread

Thread

No.

Manufacturing Operations Requirements

Stitch Type Stitching

Inch

Needle

Bobbin/

Type

1

Cutting.

a. Cut all parts of the coat (cotton/nylon

sateen, cotton-nylon oxford, cotton buckram

and the knitted cloth) in strict accordance with

patterns furnished which show directional

lines, placement for components, and notches

for proper assembly of parts. Directional lines

shall be placed in the warp direction. The

hood, waist tunnel strip, and pocket flap lining

may be cut in the warp or filling direction. The

pocket openings may be pre-cut (see operation

11.b.).

b. Cut basic material parts of coat from one

piece of material except lower pocket bearers

and welts, flap linings, undercollar, waist

tunnel strip, neck reinforcement, button and

buttonhole reinforcement pieces, hood eyelet

reinforcement pieces, hood tunnel piece, lower

inside hanging pockets, and front interlining,

which may be cut from ends. Parts cut from

ends shall approximate the shade of the coat,

except that the waist tunnel strip, front

interlining (cotton oxford or fusible cloth), and

reinforcement pieces need not approximate nor

match the shade of the coat.

c. Sleeve linings (cotton/nylon oxford) may

be cut from ends but shall approximately

match each other.

d. Cut hood tunnel piece from cotton-nylon

oxford on the bias, 1-3/4 + 1/8 inches wide and

of sufficient length to encompass the face

opening. The tunnel piece may be strip cut and

placed on rolls.

e. Cut drawcords in lengths as follows

(measurements in inches):

XS

S

M

L

XL

Tol.

Waist drawcord (one each)

44

48

52

56

60

+1

Bottom drawcord (one each)

50

54

58

62

66

+2, -1

Hood drawcord (one each)

34

34

34

34

34

+1

12

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business