MIL-DTL-6279M

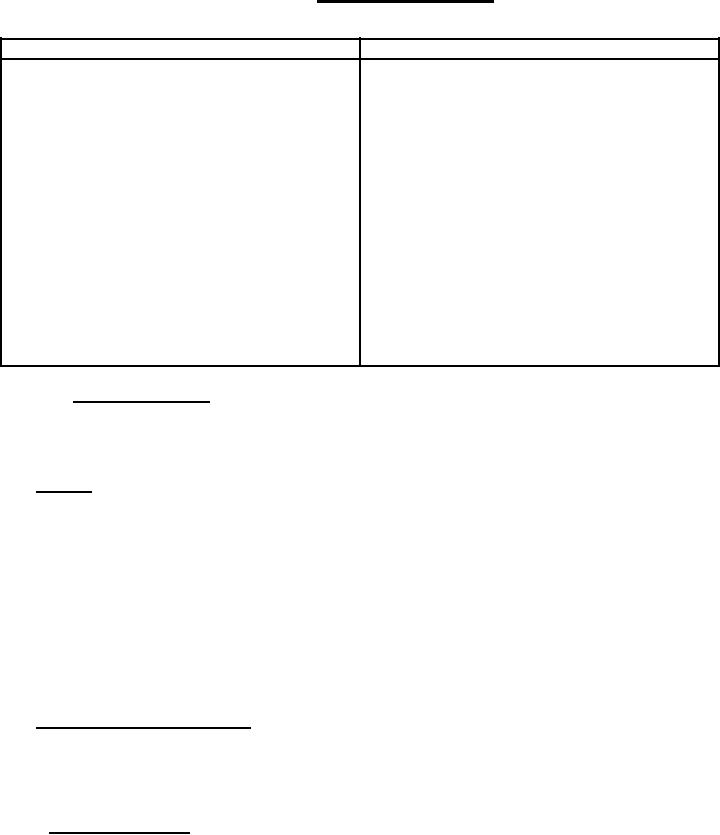

TABLE II. Length of slide fastener

SIZE

LENGTH (INCHES)

Extra extra small

24-1/2

25

Extra small

Small

25-1/2

Medium

26

26-1/2

Large

Extra large

27

Extra extra large

27-1/2

3.2.14.1 Slide fastener tape. The tape shall be 100% polyester and dyed cotton to approximate

the shade of the outer-shell material before oxidizing treatment is applied. Darker shades of the

treated tapes will be acceptable provided that the shade of the tape before treatments and after

dry cleaning meet the specified color requirements.

3.3 Design. The parka shall be single-breasted. The front closure of the parka shall have a

protective flap with a loop and button closure and another protective flap beneath running the

full closure of the slide fastener. Beneath the right front (as worn) slide fastener there shall be a

protective flap running the full course of the slide fastener, another protective flap with a loop

and button closure shall be positioned over the left slide fastener. The parka shall incorporate a

mouton-lined hood with fur face trimming. The size of the hood shall be adjustable by means of

a 4-bar, friction-type slider, a hood strap, and a tunneled drawcord. The waist of the parka shall

be adjusted by a tunneled drawcord. The parka shall incorporate two welt-type slash pockets

constructed of the outer-shell fabric and closed by snap fasteners. The parka shall also have two

lower inside hanging pockets with flaps and snap fastener closures. Reinforcement patches

constructed of the outer-shell fabric shall be provided at the elbows of the sleeves and the left

sleeve shall contain a utility pocket.

3.4 Stitches, seams and stitchings. Stitches, seams, and stitchings used in the construction of the

parka shall conform to ASTM D-6193. Wherever two or more methods, of seams, or stitches are

specified for the same operation, any one of them may be used. Where stitch type 401 is used,

the longer (under thread) shall be on the inside of the garment.

3.4.1 Type 301 stitching. Ends of all stitching shall be backstitched or overstitched not less than

1/4 inch except where ends are turned under or caught in other seams or stitching. Ends of a

continuous line of stitching shall overlap not less than 1/2 inch. Thread tensions shall be

maintained so that there will be no loose stitching resulting in loose bobbin or top thread or

excessively tight stitching resulting in puckering of the materials sewn. The locks shall be

imbedded in the materials sewn.

6

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business