MIL-DTL-44419A

3.3.1.6 Stitch tearing strength. At least 80 percent of the specimens tested shall have a stitch

tearing strength of not less than 17 pounds for the leather when tested as specified in 4.4.4.

3.3.1.7 Elongation. At least 80 percent of the specimens tested shall have an elongation of not

less than 25 percent at a load of 25 pounds. Any specimen which ruptures or exhibits grain crack

below 25 pounds shall be reported as a failing specimen. Testing shall be tested as specified in

4.4.4.

3.3.1.8 Shrinkage temperature. The leather shall not shrink before the temperature reaches

98°C + 0.5°C, nor shall the leather shrink when subjected to a temperature of 98°C + 0.5 °C for a

period of 30 seconds when tested as specified in 4.4.4.

3.3.1.9 Stiffness. At least 80 percent of the specimens tested shall have maximum stiffness

values of 120 degrees before soaking and 135 degrees after soaking when tested as specified in

4.4.4.

3.3.1.10 Water absorption resistance. At least 80 percent of the specimens tested shall gain not

more than 20 percent of their weight by water absorption when tested as specified in 4.4.4.

3.3.1.11 Moisture Vapor Transmission Rate. The leather must meet component requirements

for Moisture Vapor Transmission Rate (MVTR). At least 80 percent of the specimens tested shall

have a MVTR value of not less than 500 grams/square meter/24hours when tested as specified in

4.4.4.

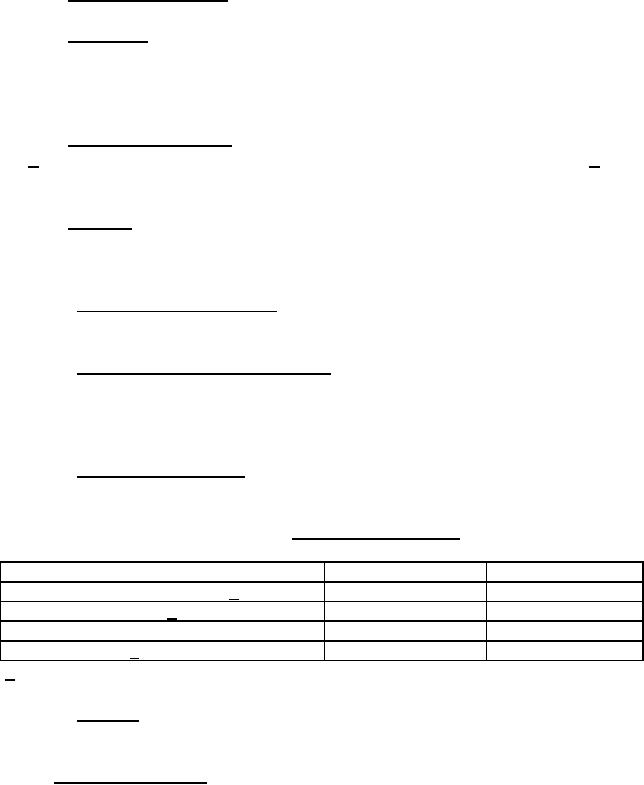

3.3.1.12 Chemical requirements. The leather shall conform to the chemical requirements in

Table I when tested as specified in 4.4.4.

Table I. Chemical requirements

Characteristics

Minimum

Maximum

Hexane soluble material, percent 1/

25.0

Chromic oxide, percent 1/

3.0

pH value

3.3

Total ash, percent 1/

9.0

1/ Calculated on moisture-free basis.

3.3.1.13 Toxicity. The finished glove shall not present a health hazard when used as intended

and tested as specified in 4.4.4.

3.3.2 Fabric, back of hand. The fabric shall be made of a highly water repellent, 4 way stretch

material consisting of 91% Nylon and 9% Spandex. The finished cloth shall conform to the

requirements specified in Table II when tested as specified in 4.4.4. The color for the fabric, back

of hand, shall be Foliage Green 504. (See 6.5)

6

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business