MIL-DTL-44419A

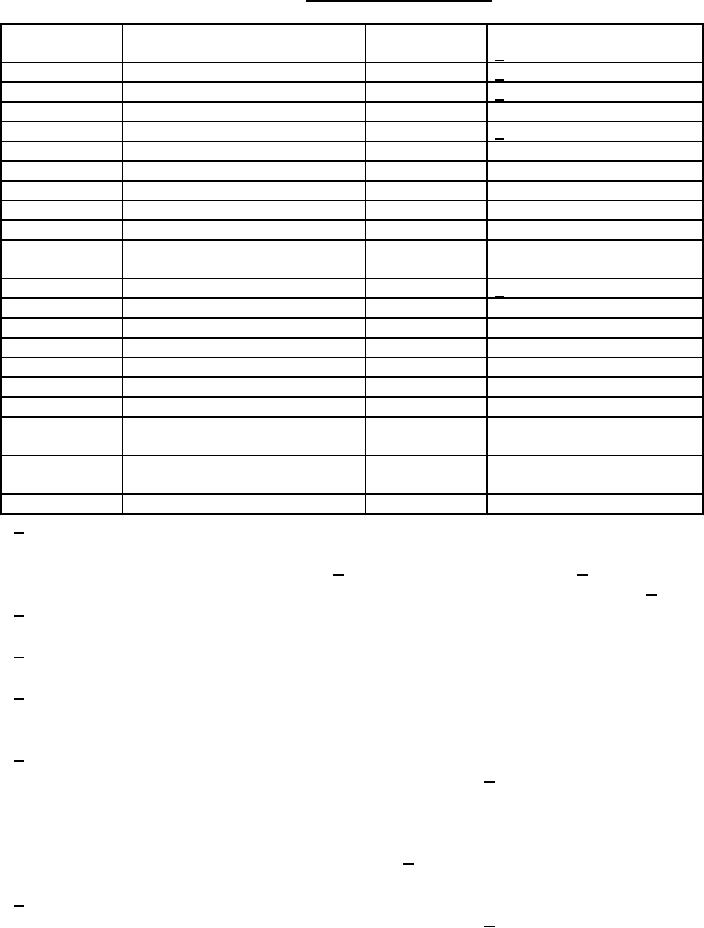

Table XII. End item testing (cont'd).

Tape (wrist

strap)

Color

3.3.6

1/

Glove hook

Color

3.3.7

1/

Thread

Color

3.3.9

1/

Nosewipe

Fiber Identification

3.3.10

ASTM 629 or ASTM 20A

Color

3.3.10

1/

Weight

3.3.10

ASTM D 3776

Crocking

3.3.10

AATCC-8

Tear Strength

3.3.10

ASTM D-2261

Surface Abrasion

3.3.10

ASTM D-3884

Water repellency

3.3.10

AATCC-22

Fleece snow

cuff

Fiber Identification

3.3.11

ASTM 629 or ASTM 20A

Color

3.3.11

1/

Weight

3.3.11

ASTM D-3776

Colorfastness Crocking

3.3.11

AATCC-8

Stretch

3.3.11

ASTM D-2594

Dimensional Stability

3.3.11

AATCC-135

Pilling

3.3.11

ASTM D-3511

Water repellency

3.3.11

AATCC-22

Thermo-

regulation

Clo, finished glove

3.4

4.5.5

Liner

retention

Liner retention test

3.5

4. 5.6

Leakage

Whole glove leak test

3.6

4. 5.7

1/ For Visual shade matching, the color and shade shall match the standard sample when viewed

using AATCC Evaluation Procedure 9, Option A, with sources simulating artificial daylight D75

illuminant with a color temperature of 7500K + 200K, with illumination of 100 + 20 foot-candles

and shall be a good match to the standard sample under incandescent lamplight at 2300K + 200K.

2/ The finished lining thickness shall be measured on panels using a 12" x 12" calibrated

Measure-Matic Thickness Gauge, or equivalent, under a pressure of 0.002 pounds per inch (psi).

3/ Five 3.5 inch diameter circle specimens shall be tested. The individual and mean weight of

the five specimens shall be reported to the nearest 0.1 ounces per square yard.

4/ Five 3.5 inch diameter circle specimens shall be tested. Pressure foot shall be 1.129

inches diameter applying a load of 0.125 lbs/inē. The individual and mean thickness of

the five specimens shall be reported to the nearest 0.001 inches.

5/ The hand side of the insert shall face the water. [Please note the insert may be inverted in use;

please refer to end item.] The free stream air velocity shall be 550 + 50 fpm as measured two

inches above the fabric specimen. The airflow shall be measured at least 2 inches from any other

surface. The test shall be run for 24 hours and weight measurements shall be taken at only the

start and completion of the test. At the start of the 24-hour test period, the air gap between the

water surface and the back of the specimen shall be 3/4 + 1/16 inch. Five specimens shall be

tested.

6/ The hand side of the insert shall face the water. [Please note the insert may be inverted in use;

please refer to end item.] The free stream air velocity shall be 550 + 50 fpm as measured 2 inches

above the fabric specimen. The airflow shall be measured at least 2 inches from any other surface.

20

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business