MIL-DTL-44419A

Sampling for inspection shall be performed in accordance with ASQC Z1.4, and with quality

acceptance limits as specified in the contract and/or order except where otherwise indicated.

4.4 Component and material inspection.

4.4.1 In-process inspection. Inspection shall be made at any point or during any phase of

manufacturing to determine whether the components are as specified or operations and/or

assemblies are accomplished as specified. The Government reserves the right to exclude from

consideration for acceptance any material or service for which in-process inspection has indicated

non-conformance.

4.4.2 End item visual examination. The finished gloves shall be examined for the defects

listed in Table XI and for the dimensional measurements examination in 4.4.3. The lot size shall

be expressed in units of gloves. The sample unit shall be one pair of gloves and selection shall be

by pairs. Defects for pairing shall be classified as a single defect.

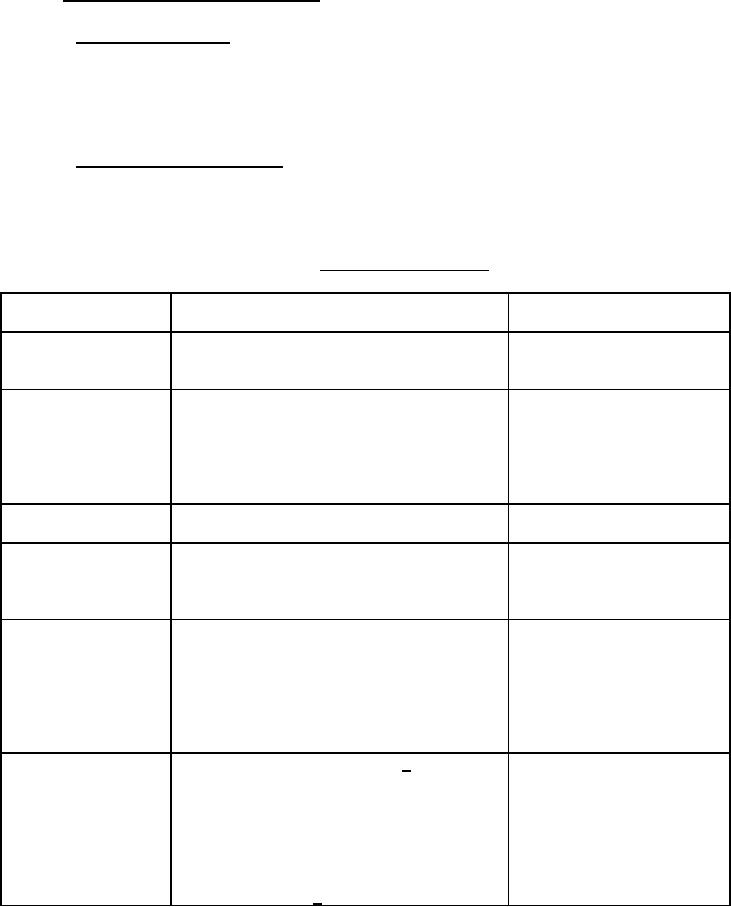

Table XI. End item visual defects

Classification

Examine

Defect

Critical Major Minor

Not matched and paired, right and left not

101

Glove

Pairing

same size, wide variation in appearance

Not tacked or joined together as specified

201

102

Shell or lining design

Not as specified (incorrect material, pattern,

etc.)

202

Poorly shaped

103

Bartacks missing, insecure, misplaced, not

specified size, stitches loose or broken,

bartack not serving intended purpose

Cleanness

Spots or stains clearly noticeable affecting

203

appearance

104

Not specified color

Leather

204

Color

Color not uniform on grain side

105

Color does not completely penetrate leather

from grain side through flesh side

106

Finish

Not full grain Flesh side not smooth or contains

areas of coarse loose fiber

107

Grain surface has application of finish

Embossing other than a fine hair cell pattern

108

Printed design on leather

109

Does not match standard sample for fine

110

hair cell pattern

205

111

Quality of leather

Not clean; stain or foreign matter 1/

112

Hard, boney, loose, spongy leather, hard

scar, cut, hole (except a pinhole or needle

hole), brittle, thin spot, brand, scratch,

deep fat wrinkle, or grain damage which

causes more than a 12 percent in total area

of a side or more than a 6 percent loss in

total area of a skin 1/

15

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business