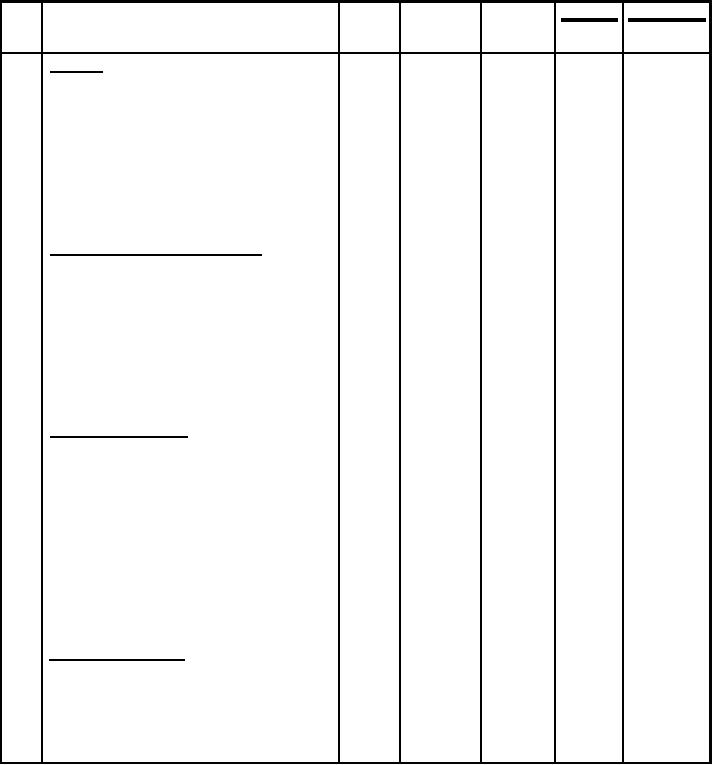

MIL-DTL-43549D

STITCH

SEAM AND

STITCHES

THREAD

TABLE II (cont'd)

TYPE

STICHING

PER

MANUFACTURING OPERATIONS

BOBBIN/

TYPE

INCH

N0.

REQUIREMENTS

NEEDLE

LOOPER/

1.

Cutting. (cont'd)

f. Cut the 1-inch wide elastic webbing for

the back adjustment strap (one each) of

sufficient length to finish 2 to 2-1/4 inches

when attached to cap (see operation 14).

g. Cut the nylon fastener tapes by

patterns.

2.

Replacement of damaged parts.

During the spreading, cutting, and

manufacturing process, components

having defects or damages that are

classified as defects in 4.4.3 shall be

removed from production and replaced

with non-defective and properly matched

components.

3.

Component marking.

a. Any method of marking may be used

except:

1. Corrosive metal fastener devices

2. Sew-on tickets

3. Adhesive tickets which leave an

impression or traces of paper or

adhesive on the material after

removal of the ticket.

4.

Make forehead flap.

Finished appearance. The forehead flap

shall be smooth and free of wrinkles and

puckers. Raised stitching shall be neat

and evenly gaged.

9

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business