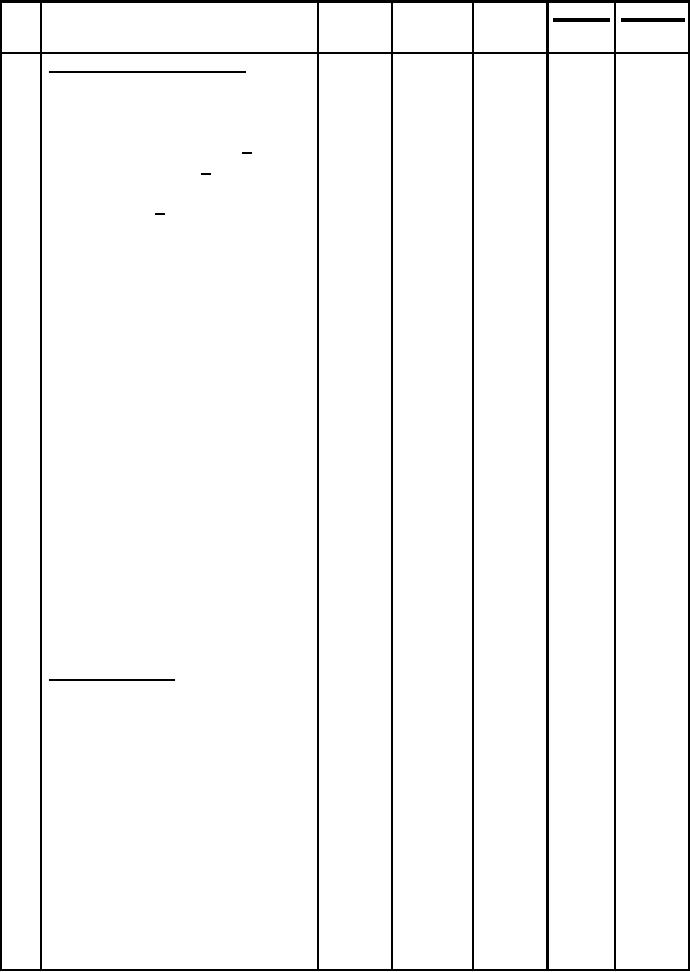

MIL-DTL-43549D

STITCH

SEAM AND

STITCHES

THREAD

TABLE II (cont'd)

TYPE

STICHING

PER

MANUFACTURING OPERATIONS

BOBBN/

N0.

TYPE

INCH

REQUIREMENTS

NEEDLE

LOOPER/

7.

Make lining and attach labels. cont'd)

c. Stitch gusset lining piece to top

301 or

LSq-2 (a)

10-14

50-2

50-2

crown lining piece.

401

LSq-2 (a)

10-14

50-2

70-2

d. Precrease sweatband 3/8 + 1/6 inch

along top edge and 5/8 + 1/16 inch

along bottom edge. The sweatband

shall measure 1 + 1/18 inch wide on the

finished cap.

e. Stitch top crown lining and attach

301or

LSq-2 (a)

10-14

50-2

50-2

gusset to side crown lining pieces and

401

LSq-2 (a)

10-14

50-2

70-2

earlap linings with each end of the

sweatband caught in the seaming. The

bottom edge of the side crown lining

pieces shall be inserted between the 5/8

inch fold of the sweatband. The earlap

linings shall overlap the bottom edge of

sweatband 3/8 inch. The ends of the

sweatband and earlaps may be tacked

to hold in position. The side crown

darts shall be turned toward the center

crown.

f. Turn seams toward top crown and

301

LSq-2(b)

10-14

50-2

50-2

raise stitch 1/8 to 3/16 inch across back

both sides of top crown. The raised

stitching may extend to bottom of

sweatband.

8

Attach sweatband.

a. Stitch the top folded edge of

301

LSd-1

10-14

50-2

50-2

sweatband to the crown lining 1/16 to

1/8 inch from folded edge.

b. Insert the bottom edge of crown

301

SSw-2(a)

10-14

50-2

50-2

lining between the 5/8 inch fold of

sweatband and stitch to crown lining

1/16 to 1/8 inch from raw edge of

sweatband.

NOTE: The sweatband need not be

precreased (operation 7.d) if

conformance to all other requirements

has been met.

188p12" style="font-size:12px">12

Downloaded: 2014-09-28T11:49Z

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business