MIL-DTL-43549D

STITCH

SEAM AND

STITCHES

THREAD

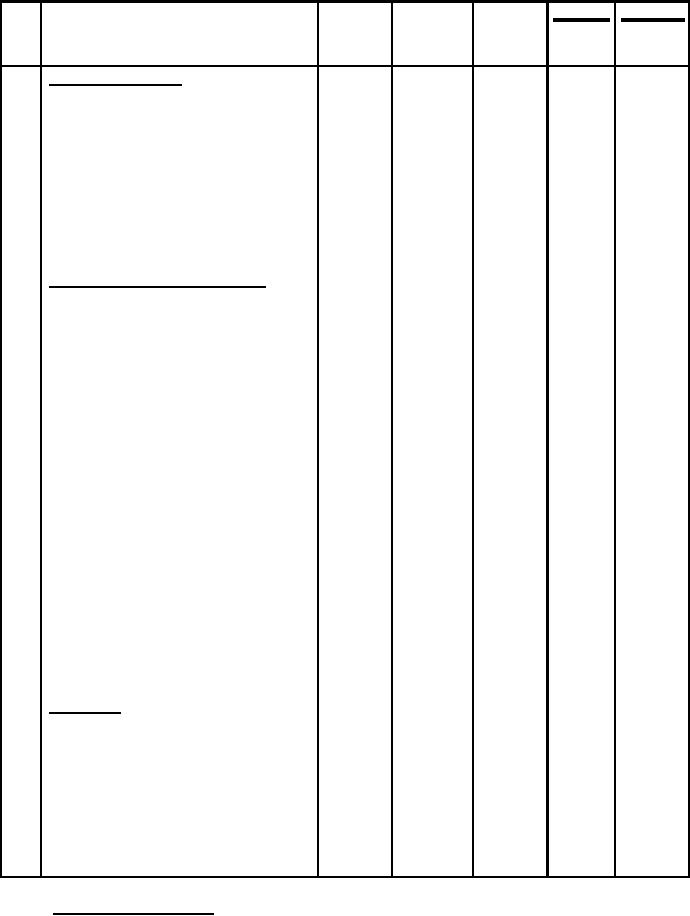

TABLE II (cont'd)

TYPE

STICHING

PER

MANUFACTURING OPERATIONS

BOBBIN/

TYPE

INCH

REQUIREMENTS

NEEDLE

LOOPER/

N0.

14

Attach back elastic.

Center elastic webbing on back of

301

10-14

50-2

50-2

earlap inch and box stitch. The box

pattern shall measure 13/16 to 7/8 inch

in length by 3/16 to 1/4 inch in width.

Ends of stitching shall be overlapped

with not less than 3 stitches. This

operation may be performed on an

automatic stitching machine.

15.

Attach fastener tapes to earlaps.

Position the loop portions of the

301

LSbj-1

10-14

B

B

fastener tape on inside of left earlap

and hook portions on the outside of

right earlap as indicated by marks on

pattern. Stitch each piece to the earlap

along all edges (including each abutted

edge) with the stitching not less than

1/16 inch from the edge. Continue

stitching through the center (1/8 inch

tolerance of center) with stitching

parallel to the sides (see Figure 1). The

end(s) of the stitching shall be

overlapped not less than 1/2 inch. One

side of the fastener tape shall be

tangent to the binding on face opening.

The line of stitching through the center

of the hook tapes may be continuous by

pivoting one inch from the bottom of

the diagonally position tape.

16.

Clean cap.

a. Trim all thread ends to 1/4 inch

maximum and remove loose threads on

inside and outside of cap.

b. Remove all shade markings or

tickets.

c. Clean all spots and stain.

3.9.1 Finished measurements, The finished caps shall conform to measurements for each respective

size, as shown in Table III.

136p15" style="font-size:12px">15

Downloaded: 2014-09-28T11:49Z

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business