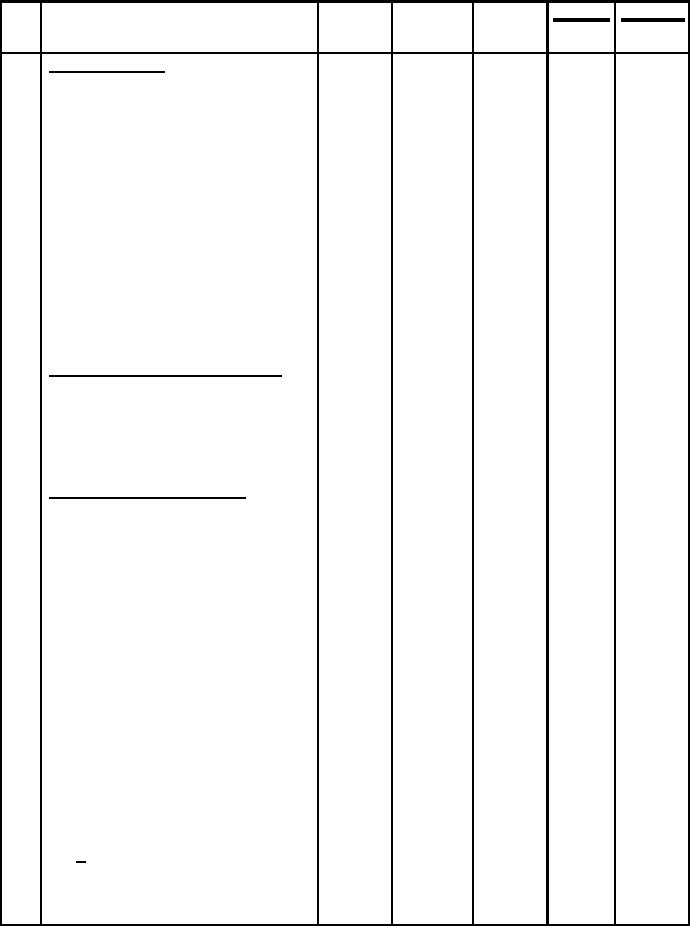

MIL-DTL-43549D

SEAM AND

STITCHES

THREAD

TABLE II (cont'd)

N0.

STITCH

STICHING

PER

MANUFACTURING OPERATIONS

BOBBIN/

TYPE

TYPE

INCH

REQUIREMENTS

NEEDLE

LOOPER/

5.

Make outer shell. (cont'd)

f. Slash seam at top of gusset; turn

301

LSq-2(b)

10-14

50-2

50-2

crown seam toward center; turn gusset

seams toward front of crown. Raise

stitch around crown 1/8 to 3/16 inch

from folded edge beginning at face

opening, extending to and across gusset

seam, ending at opposite crown seam

face opening.

-or

g. Raise stitch crown 1/8 to 3/16 inch

301

LSq-2(b)

10-14

50-2

50-2

from folded edges, the raise stitch

gusset seam 1/8 to 3/16 inch from

folded edge.

6.

Make perforations in earlap linings.

Make perforations in each earlap

lining as indicated by marks on pattern.

The perforations shall be free of ridges

and rough or hard edges.

7.

Make lining and attach labels.

Finished appearance. The lining

pieces shall be neatly joined without

twists, puckers, or pleats and with

joining seams matching the outer crown

pieces. The top and side pieces shall

be well shaped. The labels shall be

centered, straight, and the stitching

shall not be through the printing.

a. Stitch folded darts of the side crown

301

OSf-1

10-14

50-2

50-2

tapering to nothing 1/2 to 5/8 inch

beyond end of dart.

50-2

b. Center instruction label on right side

301

LSbj-1

8-14

50-2

Of crown lining and the combination

identification-size label on the left side

crown lining and stitch on all four sides

1/8 + 1/16 inch from edge. The labels

shall be on the unnapped surface. The

stitching shall not go through the

printing.

160p11" style="font-size:12px">11

Downloaded: 2014-09-28T11:49Z

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business