MIL-DTL-43549D

STITCH

SEAM AND

STITCHES

THREAD

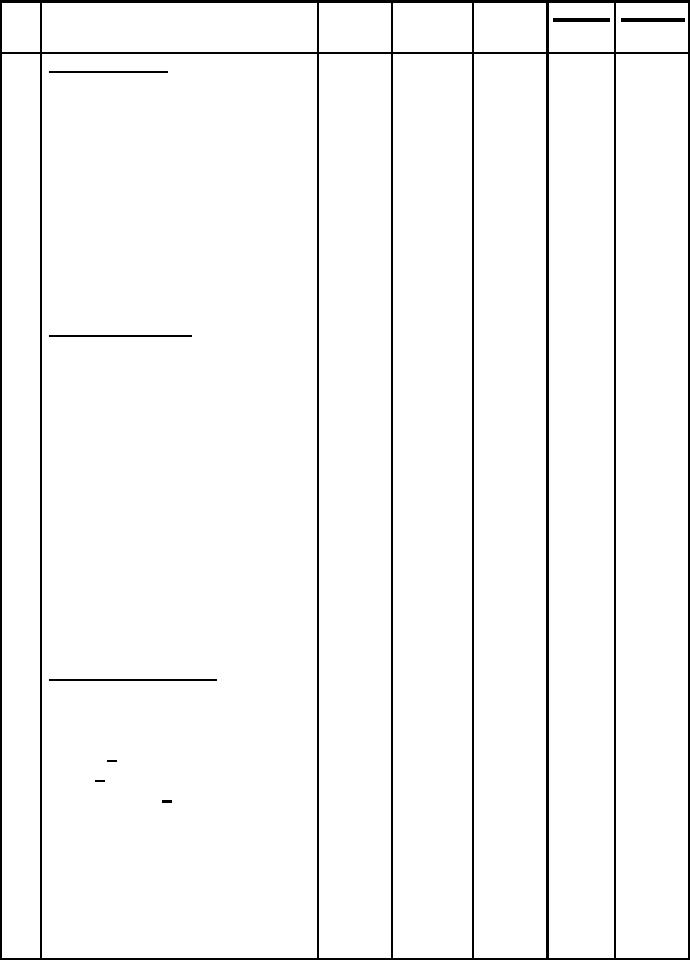

TABLE II (cont'd)

TYPE

STICHING

PER

N0.

MANUFACTURING OPERATIONS

BOBBIN/

TYPE

INCH

REQUIREMENTS

NEEDLE

LOOPER/

11.

Finish sweatband.

Using the earlap-to-lining joining seam

301

Lse-1

10-14

50-2

50-2

as a guide, place lower (folded edge of

sweatband on top of earlap). Turn in

the raw edge of sweatband on top of

earlap. Turn in raw edge at front, and

on outside stitch sweatband to cap

through all plies 1/16 to 1/8 inch from

edge (from gusset seam to gusset

seam), securely tacking each end of

sweatband. Do not distort the fabric on

the inside of the cap.

12.

Attach forehead flap.

a. Center forehead flap (loop side up)

301

10-14

50-2

50-2

on outside front of crown, so that the

overedged straight edge of flap is 1/4 to

3/8 inch up from crown edge at center

and each end is even with crown-to-

earlap joining seam. Stitch flap to

crown through all plies, 1/4 to 5/16 inch

from bottom edge, with the chain ends

(see operation 4.b) folded under the

flap and caught in the stitching.

b. Bartack each end of flap with 1/2

inch horizontal bartacks which shall

Bartack

28 per

50-2

50-2

superimpose the ends of the stitching of

Bartack

operation 12.a.

Make earlap buttonholes.

13.

Make buttonhole in each earlap with

eyelet end toward the front, positioned

Buttonhole

parallel to the sweatband stitching

50-2

50-2

76-80 per

buttonhole

(canting + 3/16 inch) with eyelet 2

or

or

including

inches + 1/8 inch from the face opening

B

B

tack

and 1-5/8 inches + 1/4 inch from the

sweatband stitching (over gusset) at

marks, as indicated on pattern; turn in

each raw end 3/16 to 5/16 inch.

167p14" style="font-size:12px">14

Downloaded: 2014-09-28T11:49Z

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business