MIL-DTL-85040D

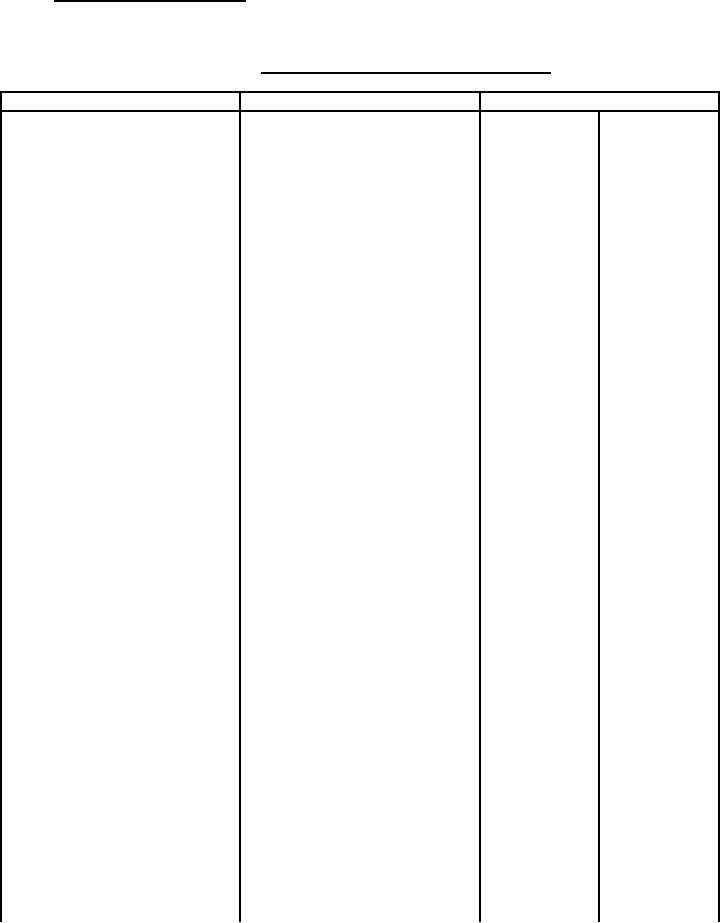

4.4.2. End item visual inspection. The end items shall be examined for the defects listed in Table

VI. The lot size shall be expressed in units of drawers or undershirts. The sample units shall be

one drawer or undershirt.

TABLE VI. Classification of end item visual defects

Examine

Defect

Classification

GENERAL

a. Any hole, cut, tear, mend,

101

burn or weakening defect such

as smash, multiple float, loose

slub, needle chew, or abraded

area.

b. Any portion of any drawers

102

or undershirt, as applicable,

stiffened, hardened, or

scorched by any process of

manufacturing

c. Any unsightly slub, spot, or

201

stain; any discoloration of the

cloth caused by the removal of

any size marking ticket; any

size marking ticket, excluding

the metal fastening or sewn-on

kind, not removed; or any size

marking adhesive mass

adhering to the cloth

d. Any size marking

103

identification stamping visible

on the outer-side of any

drawers or undershirt, as

applicable;

e. Any metal fastening device

202

or sewn-on size marking

ticket.

f. Three or more thread ends

104

or sewn stitching end not

trimmed to a maximum length

of 3/8 inch or three or more

thread scraps not removed.

g. Any run or dropped stitch

203

h. Any snag, pull, slubby yarn,

105

or knit too tight or loose

(lacking of elasticity)

11

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business