MIL-DTL-29112D

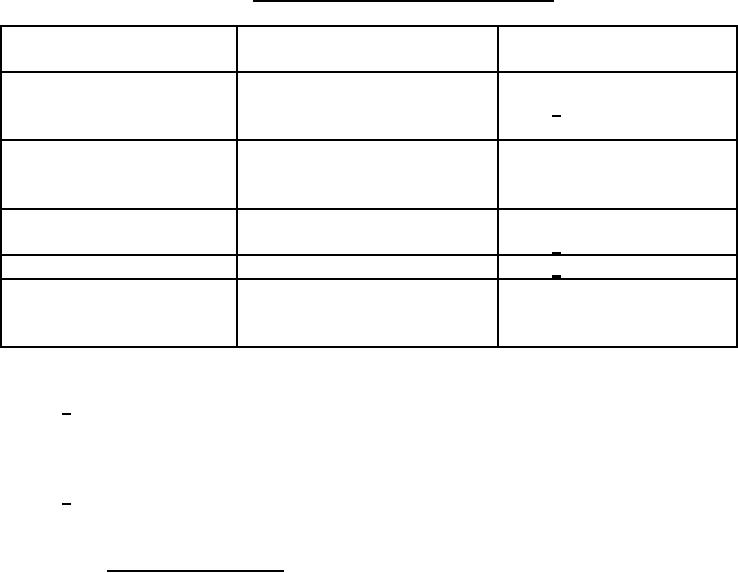

TABLE VII. Component and material inspection (contd.)

CHARACTERISTICS

REQUIREMENT PARAGRAPH

TEST METHOD

Thread

Fiber Identification

3.3.2

Visual 1/

Breaking strength (lb.)

3.3.2

ASTM D2256

Button:

Compressive strength

3.3.3

4.4.4

Resistance to water

3.3.3

4.4.5

D-rings

Material identification

3.3.4

Visual 1/

Gimp

3.3.5

Visual 1/

Labels:

Colorfastness to

3.3.8

AATCC-61, Test IVA

laundering

1/ A Certificate of Compliance is acceptable. Where certificates of compliance submitted, they

shall contain verifiable actual test and inspection data. The Government reserves the right to inspect and

test the material or components to verify the validity of the certification.

2/ Use Opt. Vc, for washing and Opt. D for drying. (The sample should not be subjected to

restorative procedure.)

4.4.2 End item visual inspection. The end items shall be examined for the defects listed in

Table VIII. The lot size shall be expressed in units of swimmers trunks. The sample unit shall be one

trunk.

12

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business