MIL-DTL-29112D

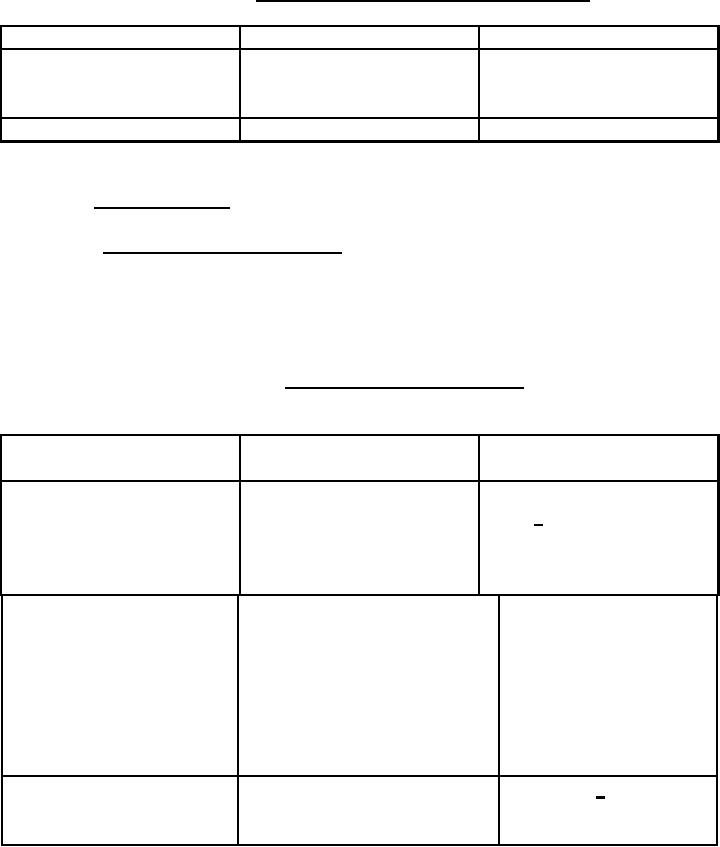

Table VI: Conformance Inspection Examinations and Tests.

INSPECTION

REQUIREMENT

INSPECTION METHOD

Visual Examination

3.5, 3.7, 3.7.1, 3.7.2, 3.7.3,

4.4.2

3.7.4, 3.7.5, 3.7.6, 3.7.7, 3.8,

3.8.1, 3.10

Dimensional Examination

3.9

4.4.3

4.4 Inspection methods.

4.4.1 Component and material inspection. In accordance with 4.1, components and materials

shall be tested in accordance with all the requirements of referenced specifications, drawings and

standards unless otherwise excluded, amended, modified or qualified in this specification or applicable

procurement documents. In addition, testing shall be in accordance with Table VI.

TABLE VII. Component and material inspection

CHARACTERISTICS

REQUIREMENT

TEST METHOD

PARAGRAPH

Basic Material

3.3.1

Fiber Identification

3.3.1

Visual 1/

Weight oz./sq. yd.

3.3.1

ASTM D3776

Tearing Strength (lb.)

3.3.1

ASTM D1424

Colorfastness (min.)

Laundering

3.3.1

AATCC-61, TM 3A

Light

3.3.1

AATCC-16 Opt. A

Perspiration

3.3.1

AATCC-15

Bleaching

3.3.1

AATTCC-3

Wet-dry cleaning

3.3.1

AATCC-132

Weathering

3.3.1

AATCC-111A

Dimensional Stability

3.3.1

AATCC-96 2/

(percentage)

3.3.1

3.3.1

11

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business