MIL-DTL-44312C

4.3 Conformance inspection. Unless otherwise specified, sampling for inspection shall be

performed in accordance with ANSI/ASQC Z1.4.

4.3.1 Examination. Each vest and hose assembly shall be examined for compliance with the

requirements specified in section 3 and subsequent government drawings. In accordance with

4.1, components and materials shall be inspected in accordance with all the requirements of

referenced documents unless otherwise excluded, amended, modified, or qualified in this

specification or applicable purchase document.

In addition, the first production lot or each of the components listed below shall be examined for

conformance to all dimensions specified on the referenced drawings. Any dimension exceeding

the applicable tolerance specified on the applicable drawing shall be classified as a defect. The

lot sizes shall be expressed in units of components. The sample unit shall be one component.

For each component lot, the inspection level shall be S-1 and the acceptable quality level (AQL),

expressed in terms of defects per hundred units, shall be 1.5. Failure of any lot shall be cause for

correction of the mold or process and for examination of the next produced lot from that mold or

process. Any subsequent lot in which a change in materials, mold, or process has occurred shall

be examined as above. If there are no changes, subsequent lots shall be accepted on the basis of

a certificate of compliance certifying that there have been no changes in materials, mold, or

manufacturing process.

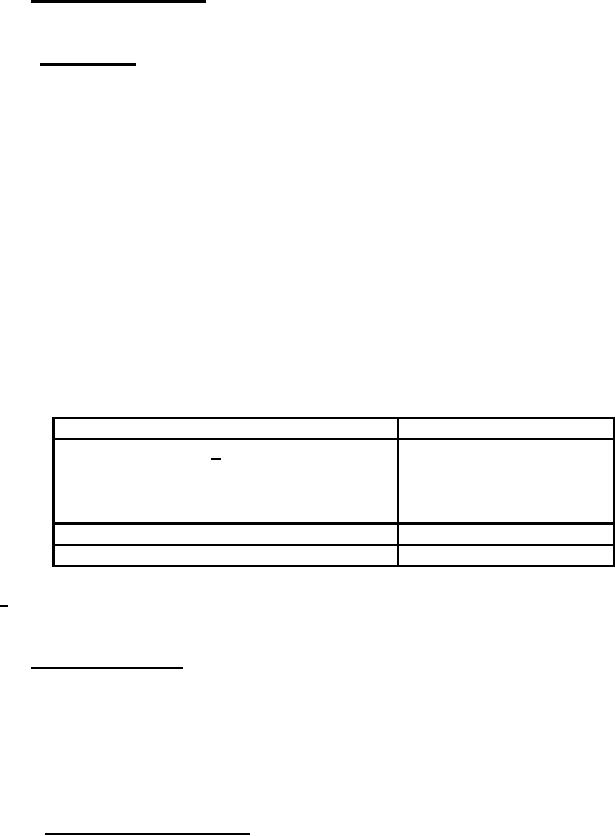

Component

Drawing

Connector assembly 1/

2-11-11

2-11-12

2-11-13

2-11-14

Back air distribution manifold

2-11-24

Front air distribution manifold

2-11-25

1/ Component must be disassembled prior to performing dimensional examination.

4.4 In-process inspection. Inspection of subassemblies shall be made to ascertain that

construction details which cannot be examined in the finished products are in accordance with

specified requirements. The Government reserves the right to exclude from consideration for

acceptance, any material or service for which in-process inspection has indicated

nonconformance. Whenever nonconformance is noted, corrections shall be made to the parts

affected and lot in process. Components that cannot be corrected shall be removed from

production.

4.4.1 End item visual examination. The end items shall be examined for the defects listed in

table I. The lot size shall be expressed in units of vests. The sample unit shall be one completely

fabricated vest. The inspection level shall be II and the AQL, expressed in terms of defects per

hundred units, shall be 1.5 for major defects and 6.5 for total (major and minor combined)

defects.

6

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business