MIL-DTL-44312C

TABLE I. End item visual defects (cont'd)

Classification

Examine

Defect

Major

Minor

Bar Code Label/Tag

Bar code omitted or not readible by

221

scanner.

Human readible interpretation (HRI)

222

omitted

Not visible on folded, packaged item.

223

Causes damage to the item.

128

4.4.4 End item dimensional examination. The end item hose assemblies shall be examined for

the defects listed in table II. For this examination, the hose assemblies shall be removed from

the sample vests and placed on a flat surface at full length with the hook tape fastener on the

manifolds facing up. The lot size shall be expressed in units of vests. The sample unit shall be

one complete vest. The inspection level shall be S-3 and the AQL, expressed in terms of defects

per hundred units, shall be 1.5 for major defects and 6.5 for total (major and minor combined)

defects.

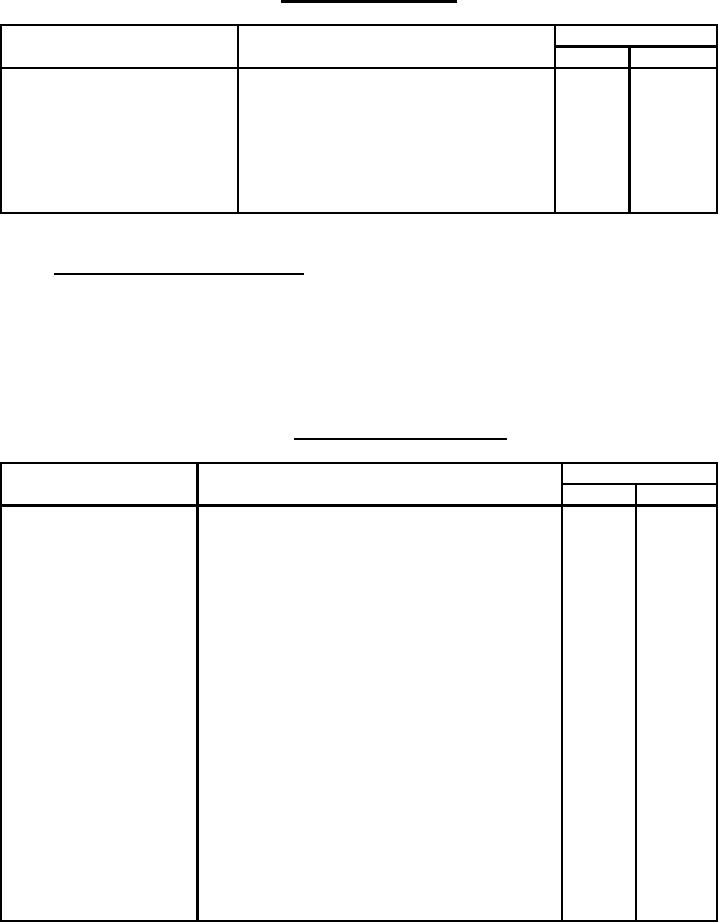

TABLE II. End item dimensional defects

Classification

Examine

Defect

Major

Minor

Large air distribution

Length more than ¼ inch more or less than

101

hose

specified tolerance

Length up to 1/14 inch more or less than

201

specified tolerance

Small air distribution

Length more than 1/8 inch more or less than

102

hose

specified tolerance

Length up to 1 /8 inch more or less than

202

specified tolerance

Cloth covered foam

Length more than 1/8 inch more or less than

103

specified tolerance (from edge of sleeve to

edge of sleeve)

Length up to 1/8 inch more or less than

203

specified tolerance (from edge of sleeve to

edge of sleeve)

Not positioned from back manifold as specified

More than 1/8 inch

104

Up to 1/8 inch

204

10

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business