MIL-DTL-44105C

3.7.2 Manufacturing cut and finish dimensions. Manufacturing cut and finish dimensions shall be as

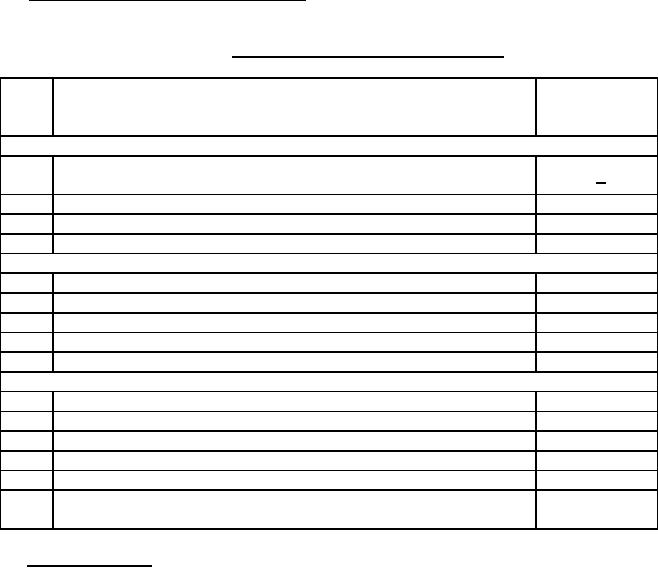

specified in Table V.

TABLE V Manufacturing cut and finish dimensions

Dimension

Item

Dimension Description

and tolerance

(inches)

CUT LENGTHS

Chin strap cut length after fusing lace ends, for use with plastic fix

1

27+1

lock keeper

2

Chin strap cut length after fusing lace ends, for use with leather keeper

25 ± 1

3

Chin strap leather keeper length

3/4 ±1/8

4

Chin strap leather keeper width

1/2 ± 1/8

BRIM

1

Finished brim

2-3/8 ± 1/8

2

Brim binding start and finish aligned to center back

± 1/2

3

Brim binding end overlap no less than

1/2

4

Binding finish width on top of brim no more than

3/8

5

Finished brim upward curvature

3/4 - 1

SEAMING OF SIDE TO CAMOUFLAGE BAND

1

Webbing bartack spacing

1-1/4 ± 1/8

2

Fullness between bartacks (webbing to side piece) forming loops

1/8 (-0/ + 1/8)

3

Webbing bartack to back seam spacing No less than

1/2

4

Webbing bartacks finished length

1/2 - 5/8

5

Webbing bartacks finished width, no more than

3/32

Instruction label or combination label distance from raw edge of side

6

3/4 -1

lining

3.7.3 Stitches and seams. Stitches and seams specified in Table VI shall conform to ASTM-D-6193.

Where two or more stitch or seam types are given for the same part of the operation, any one of them

may be used. When stitch Type 401 is used, the looper (underthread) shall be on the inside of the hat.

Seams shall be sewn so that no raw edges, open seams, run-offs, twists, pleats or puckers will result.

Seams shall start and finish evenly.

10

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business