MIL-DTL-44048H

3.4.2 Parts cut from ground shade/printed seconds/mill seconds. Table Ib lists the pattern parts which

may be cut from ground shade cloth, printed seconds, or mill seconds (see 3.3.2).

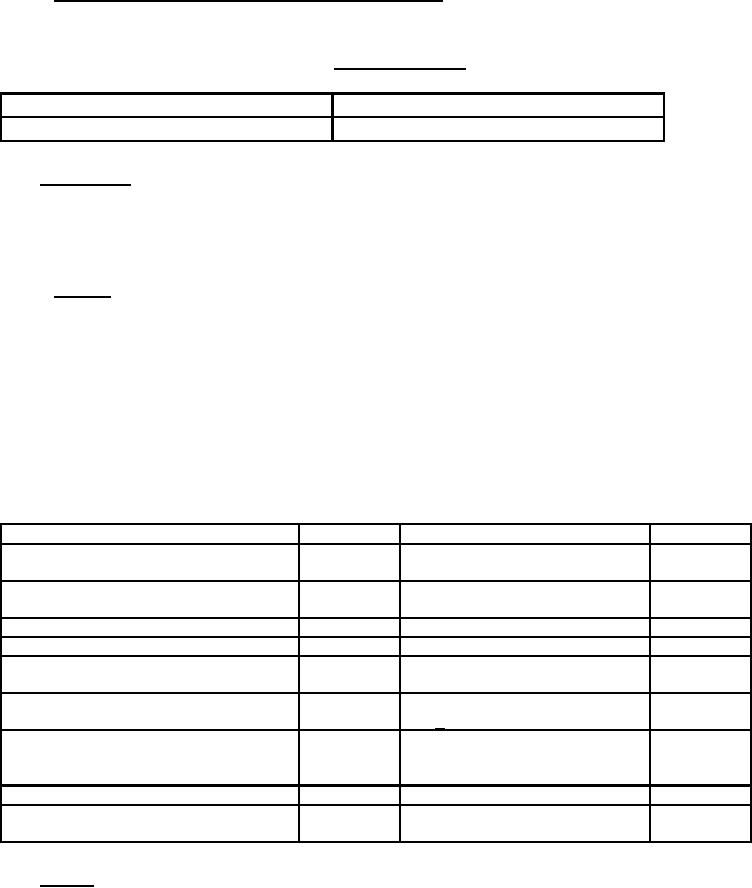

TABLE Ib. List of pattern parts.

Pattern Abbreviation

Nomenclature

PENCIL PCKT

Pencil pocket

3.5 Configuration. The following specifics are needed to provide uniform appearance, comfort, and

durability in garrison, combat, and operations other than war. End item garment construction and

appearance shall conform to figures 1 through 7 and the finished dimensions (see 4.4.9.1) to maintain

configuration and compliance to end item performance tests (see 4.4).

3.5.1 Seaming. Seaming shall be consistent, exhibit a uniform appearance and conform to the ASTM

D6193 stitch and seam types listed below. The backside of all seams (inside garment) shall be flat with

no protruding seam allowance to create irritation or discomfort. The seams shall be sewn with 10-14

stitches per inch for all outside visible stitching. Overedge or pre-hemming shall be 6-10 stitches per

inch. To maintain durability and functionality, bartacks 3/8 to 5/8 inch in length with approximately 27

stitches are required at the specified reinforcement points shown in Figure 7. Buttonholes shall be eyelet

end, tapered bar, ¾ to 7/8 inch length with 52 - 56 stitches per inch. The buttonhole purling shall be

between tab and flap plies and front facing and front plies, or on the outside of the coat. Eyelets for the

pockets shall have a minimum of 19 stitches each, with the purling on the outside. All material edges

shall be clean finished: edges shall be either turned-in, turned-under, or serged.

Seam Placement

Seam type

Gage

Stitch Type

Side seams, back arm seams, set in

LSc-2

3/16 to 9/32 inch gage

301

sleeves, shoulder seams

or 401

Top Stitching of pocket flaps, collar, left

OSf-1

316 to 1/4 inch from the edge

301

front fly, cuff, front edges

Top Stitching of pockets

OSf-1

1/16 to 1/8 inch from the edge

301

Attachment of pockets

LSd-1

1/16 to 1/8 inch from the edge

301

Attachment of patches and flaps

LSd-1or

two rows 3/16 to 1/4 inch apart

301

LSd-2

Bottom hemming

Efb-1

1/16 to 1/8 inch from edge,

301

5/8 + 1/8 inch wide hem

Attachment of flaps

LSbk-3

3/16 inch setting with 1/4 inch

301

gage topstitching or

1/16 inch with 1/4 inch gage

Setting cuff

LSd-1

1/8 to 3/16 inch from the edge

301

Setting collar

Ssa-1

1/16 to 1/8 inch from the edge

301

Lsb-1

3.6 Toxicity. The finished cloth used in the coat shall not present a dermal health hazard when used as

intended (see 4.4.7).

10

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business