MIL-DTL-81188C

3.4 Design and construction. The back of the glove and thumb, including the base of the thumb and a

portion of the gauntlet and the four finger seamless fourchette shall be fabricated from the high temperature

resistant, polyamide, simplex knitted cloth for protection from fire. The palm and the front of the gauntlet,

thumb, and fingers of the glove shall be fabricated from one piece of the leather. The gauntlet of the glove

shall contain an elastic webbing takeup. The gloves shall be constructed in accordance with figures 1 through

4. No cut edges, except where specified for the leather, shall be visible on the exterior of the glove. The

patterns, for the gloves, shall be furnished by the government.

3.4.1 Seams and stitching. All the seams used in the fabrication of the gloves shall conform to figures 1

through 4. Unless otherwise specified, the tolerances of the seams shall be plus 1/16, minus 0, inch. All

stitch and seam types shall contain 9 to 12 stitches per inch.

3.4.2 Attaching of the elastic webbing. The elastic webbing shall be centered and attached across the seam,

on the inside of the glove, in accordance with figures 1 and 3, section C-C. The webbing shall be attached in

its full stretched length so that the shirrings on the outerside, where the webbing is attached, shall be evenly

spaced and the full amount of the stretch in the webbing shall be utilized.

3.4.3 Leather stretching. The tranks shall be cut so that the stretch is in the width of the assembled

glove. The leather shall be dampened and the stretch pulled out firmly, in the length, before cutting the

leather sections. All the hard parts of the leather which do not stretch adequately shall not be cut into the

gloves. The leather parts that stretch lengthwise shall not be used

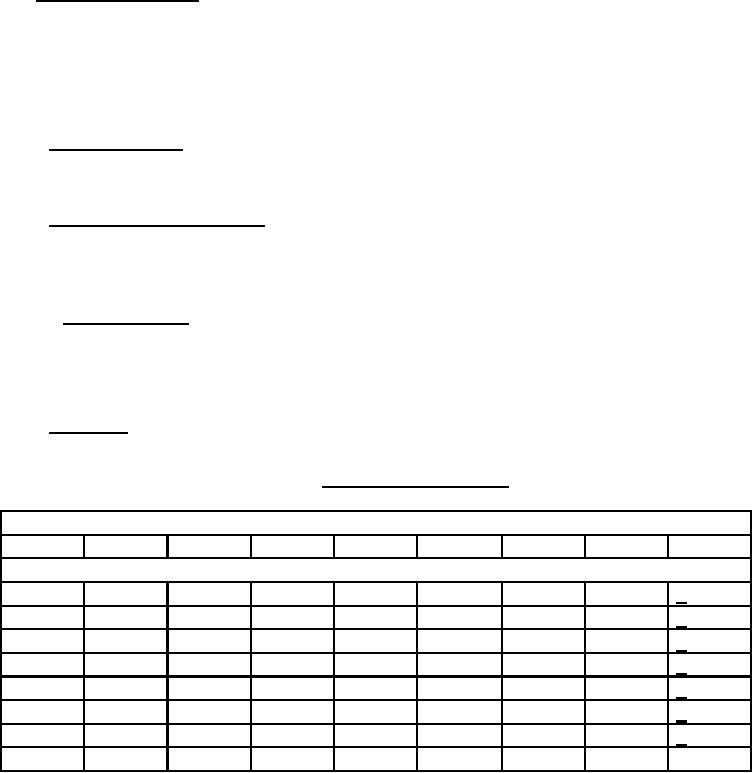

3.4.4 Dimensions. The dimensions, for the various glove sizes shall conform to Table I. The variation in the

length or width, between the left and right glove, in any pair, shall not exceed ±1/4 inch.

TABLE I. Glove Dimensions in Inches

SIZES

5

6

7

8

9

10

11

Location

Tolerance

A

12-1/4

12-1/2

12-3/4

12-7/8

13-1/8

13-3/8

13-1/2

+ 3/4

B

2-3/4

2-3/16

3

3-1/16

3-1/8

3-3/16

3-1/4

+ 1/8

C

3-7/16

3-1/2

3-9/16

3-5/8

3-11/16

3-3/4

3-13/16

+ 1/8

D

2-13/16

2-7/8

3-1/16

3-1/8

3-3/16

3-1/4

3-5/16

+ 1/8

E

2-1/4

2-5/16

2-7/16

2-1/2

2-9/16

2-5/8

2-11/16

+ 1/8

F

3

3-1/16

3-1/8

3-3/16

3-1/4

3-5/16

3-3/8

+ 1/8

G

3-5/8

3-3/4

3-7/8

4

4-1/8

4-1/4

4-3/8

+ 3/16

Stretch

3/4

3/4

3/4

3/4

3/4

3/4

3/4

min.

NOTE: See Figure 5 for location.

5

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business