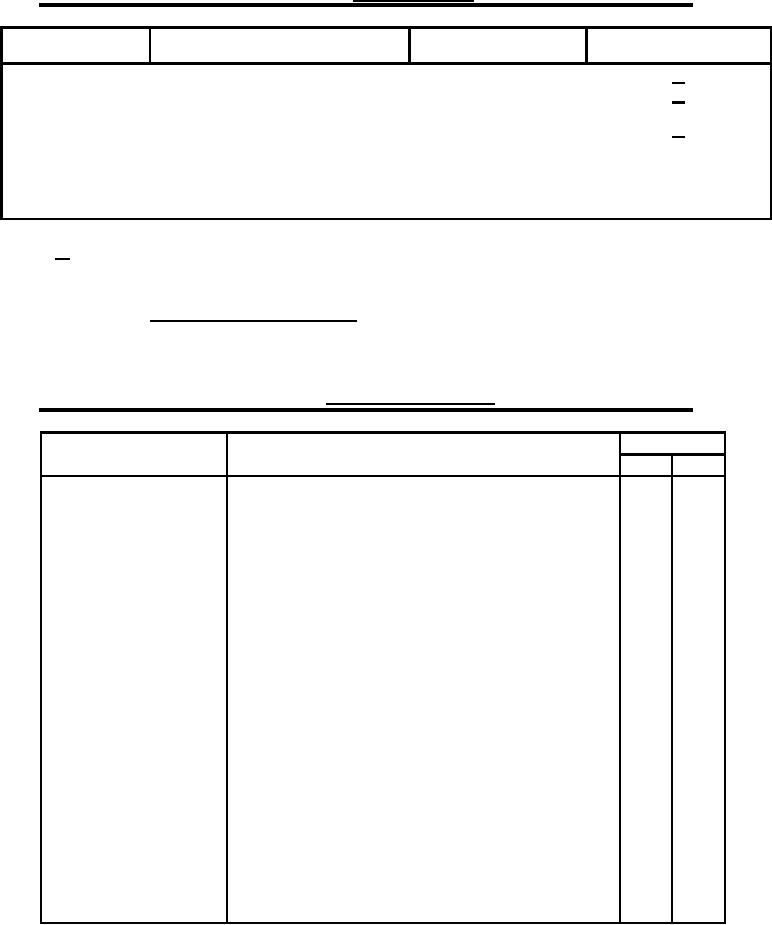

MIL-DTL-3866H

TABLE IV. Component tests

Requirement

Component

Characteristic

reference

Test Method

Cotton jersey knit

Material identification

3.2.1

1/

Type of knit

3.2.1

1/

Absence of optical bleaches

(brighteners)

3.2.1

1/

Weight per square yard

3.2.1

ASTM-D-3776

Wales and courses per inch

3.2.1

ASTM_D-3887

Bursting strength

3.2.1

ASTM-D-3787

Nonfibrous material

3.2.1.1

ASTM-D-629

1/ Unless otherwise specified, a certificate of compliance shall be submitted and will

be acceptable for the stated requirement.

4.3.2 End item visual examination. The end item shall be examined for the

defects listed in table V. The lot size shall be expressed in units of gloves. The sample

unit shall be one glove and the selection shall be by pairs. The inspection level shall be

I.

TABLE V. End item visual defects

Examine

Defect

Classification

Major

Minor

Paring

Not properly mated (i.e., not of same size)

101

Cleanness

Spot or stain

201

Thread ends not trimmed

202

Surplus material on seams not evenly trimmed

203

Rancid or other objectionable odor

102

Color

Other than bleached white

103

Cutting

Any component not cut on straight line and not cut with

length direction of component in wales direction

of fabric

104

Material and Workmanship

Any hole larger than 3/32 inch

105

Three or more holes

106

Two holes 3/32 inch or less located closer than 3 inches

to each other

204

NOTE: Two holes 3/32 inch or less are not to be scored

as a defect if the holes are 3 inches or more

apart. All holes shall be measured across

opening in longest dimension.

8

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business