MIL-DTL-3866H

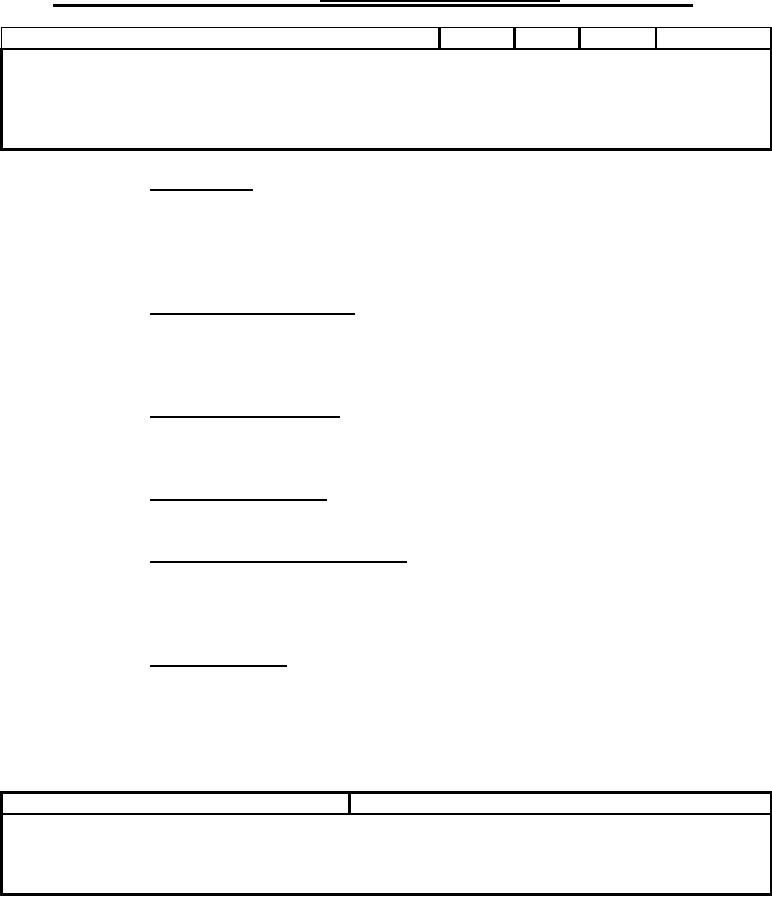

TABLE III. Measurements of finished gloves

Small

Medium

Tolerance

Characteristic

Figure 1

Total length (inches)

A

14 1/2

15

+/- 1/2

Hand width (inches)

B

3 1/2

4

+/- 1/4

Width of wrist opening

C

3 1/4

3 3/4

+/- 1/8

3.9

Workmanship. The finished gloves shall conform to the quality of product

established by this document. The occurrences of defects shall not exceed the

applicable acceptable quality levels.

4.

VERIFICATION

Classification of inspections. The inspection requirements specified

4.1

herein are classified as follows:

a.

First article inspection (see 4.2).

b.

Conformance inspection (see 4.3).

4.2

Certificates of compliance. When certificates for compliance are

submitted, the Government reserves the right to inspect such items to determine the

validity of the certification.

4.3

Conformance inspection. Unless otherwise specified, sampling for

inspection shall be preformed in accordance with ANSI/ASQC Z1.4.

4.3.1 Component and material inspection. In accordance with 4.1, components

and materials shall be inspected in accordance with all the requirements of referenced

documents unless otherwise excluded, amended, modified, or qualified in this

document or applicable purchase document.

4.3.1.1 Component testing. The finished knitted fabric shall be tested as specified

in table IV. The lot size shall be expressed in units of yards. The sample unit shall be 1

yard full width of the finished fabric. The number of sample units shall be as shown

below. The lot shall be unacceptable if one or more sample unit fail to meet any

requirement specified in Table IV. All test reports shall contain the individual values

utilized in expressing the final result.

Lot size (yards)

Sample size (sample units)

800 or less

2

801 up to and including 22,000

3

22,001 and over

5

7

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business