MIL-DTL-3866H

3.7.2.2 Type 301 stitching. Ends of 301 stitching shall be backstitched or

overstitched 1/4 inch minimum except where ends are turned under in a hem or held

down by other stitching. Thread tension shall be maintained so there will be no loose

stitching resulting in a loose bobbin or top thread or no excessively tight stitching

resulting in puckering of the materials sewn. The lock shall be embedded in the sewn

materials.

3.7.2.3 Type 401 stitching. Thread tension shall be maintained so that there will

be no loose stitching.

3.7.2.4 Repairs of stitching. Repairs of stitching shall be as follows:

a.

When thread breaks or bobbin run-outs occur during sewing, the

stitching shall be repaired by restarting the stitching a minimum of 1 inch back of

the end of the stitching.

b.

Thread breaks or two or more consecutive skipped or run-off

stitches noted during inspection of the item shall be repaired by overstitching.

The stitching shall start a minimum of 1 inch beyond the defective area onto the

existing stitching. Loose or excessively tight stitching shall be repaired by

removing the defective stitching, without damaging the materials, and restitching

in the required manner. 1/

1/ When making the above repairs, the ends of stitching are not required to be

backstitched.

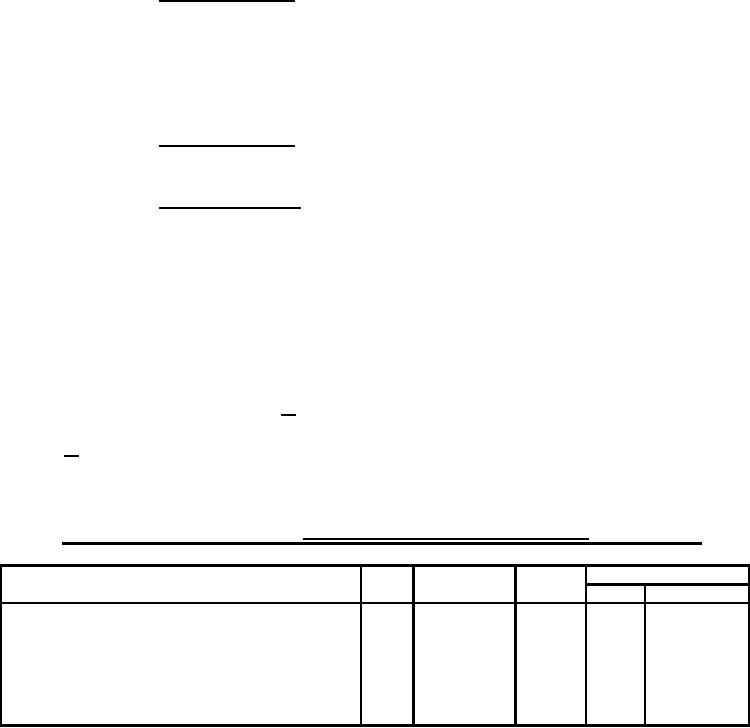

TABLE II. Manufacturing operations requirements

No. Requirements

Stitch

Seam and

Stitches

Thread

Type

Stitching Type

per Inch

Needle Bobbin/Looper

1. Cutting. The gloves shall be cut in

accordance with the patterns. There are two parts

to each glove, a front and a back. All component

parts shall be cut from the same piece of material

with the length direction (cuff to fingertip direction)

of the part running in the wale direction.

5

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business