MIL-DTL-14610H

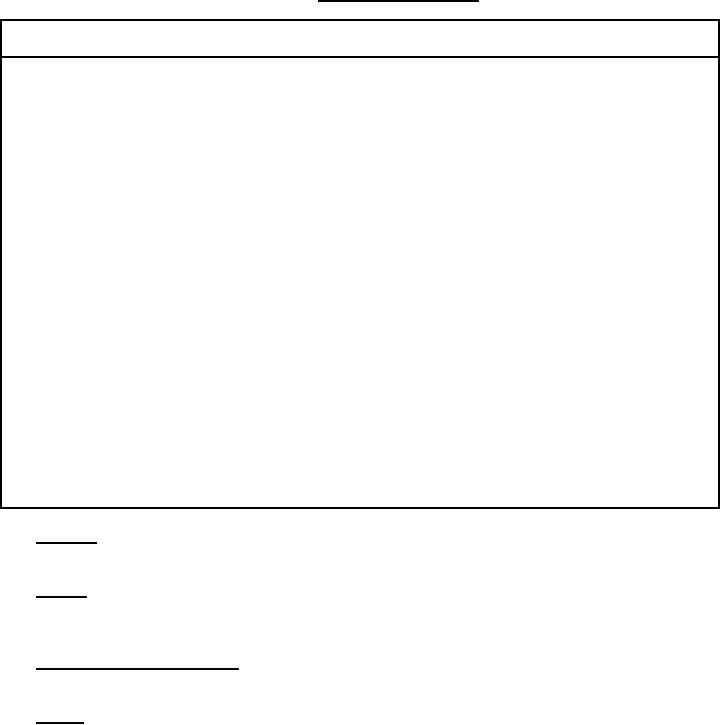

TABLE I. Physical requirements

Characteristic

Minimum

Maximum

Weight (oz per sq. yd)

-

10.5

Breaking strength, lbs.

Warp

110

-

Filling

100

-

-

Dimensional change

shall be 2% max. in either

the warp or filling direction

Air permeability (CU FT/MIN/SQ.)

10.0

-

Flame retardancy:

Initial after flame time (seconds)

-

2

percent consumed

-

40%

Flame retardancy after 15

launderings:

the initial after flame time (seconds)

-

2

percent consumed

-

40%

pH

5.0

8.5

Tear Strength (warp and fill)

6.0

-

Dynamic absorption

40%

-

3.3 Toxicity. The flame retardant treated cloth shall show no toxicity to the skin or eyes when

used as intended when tested in accordance with 4.3.4.

3.4 Thread. The thread shall be cotton thread or cotton-covered, polyester core thread. The

color of the thread shall approximate the color of the basic fabric. The minimum breaking

strength shall be 1.8 pounds when tested in accordance with paragraph 4.3.3.

3.5 Hook and loop fastener tape. The hook and loop fastener tape shall be a minimum of 1-inch

wide, white in color, and conform to Type II, Class 1 of A-A-55126.

3.6 Labels. Each coverall shall have a commercial-type size label, identification label and

instruction label. The identification label shall contain the item description, contractors name,

contract number, National Stock Number (NSN) and fiber and laundering information. The

identification and instruction label can be combined. The labels shall show durability and

colorfastness to laundering. The labels shall be sewn on all four sides to the inside center back,

below the collar. The size label shall be positioned above the identification/instruction label.

The instruction label shall contain the following inscription:

Wear as outer garment

Keep front closed to assure

body protection.

Keep sleeves adjusted.

Keep pocket clean and free

4

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business