A-A-55278A

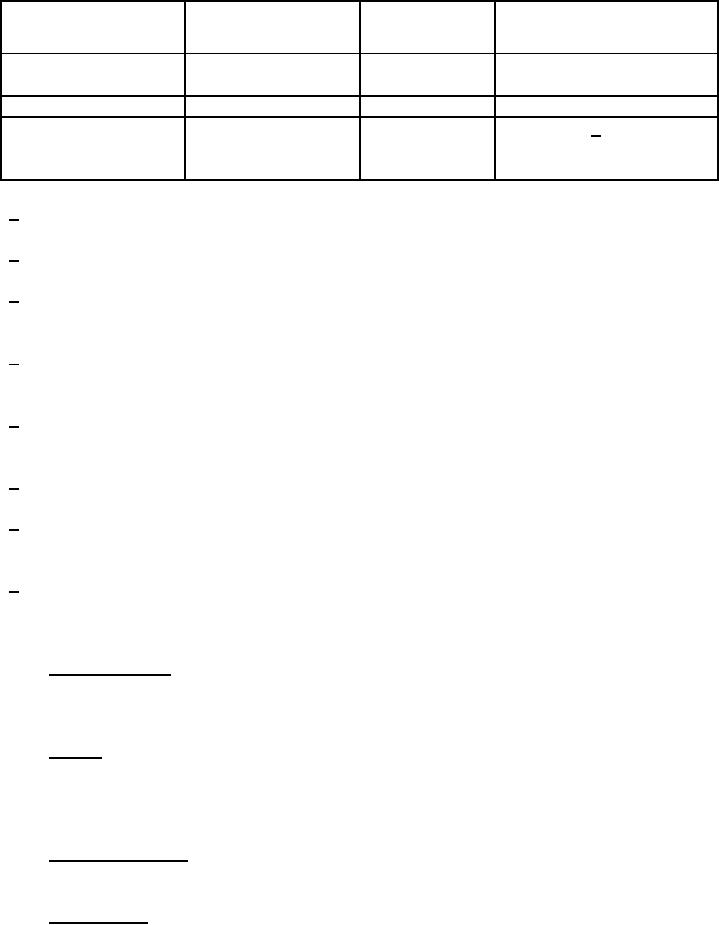

Table II - Coated Cloth Physical Requirements (continued)

No evidence of tackiness, -

Resistance to heat at

ASTM-D-5034

o

exudation, or loss of

160 F

flexibility

Adhesion of coating,

10

-

ASTM-D-751

lbs. per 2 inch width

Blocking, scale rating

-

No. 2

ASTM-D-751

AATCC 8 6/

Dusting powder

Resistance to dry

-

"good"

crocking

1/ Standard instrument with one augmenting weight.

2/ The water pressure shall be applied only to the uncoated side of the test specimens.

3/ Ten specimens shall be tested and averaged, five with the coated side up and five with the

coated side down.

4/ Prior to performing this test, the test specimens shall be conditioned for at least four hours at

the specified temperature.

5/ Prior to performing this test, the test specimens shall be conditioned for one hour at the

specified temperature.

6/ The test shall be conducted using the blue/black crock cloth.

7/ Samples shall be conditioned as directed in "D1776 Practice for Conditioning Textiles for

Testing" prior to testing.

8/ Procedure A -Pressure application by Mullen type Hydrostatic Tester, sections 34-37,

Procedure 1 (except that the rate of displacement shall be as specified in section 34.2) shall

be used.

2.2.2 Foam Interlining. The foam interlining shall be unicellular closed cell foam, 3/16 inch in

thickness, made from an expanded supersoft polyvinyl-chloride plastic material. The finished

material shall comply with U.S. Coast Guard Regulations CFR 164.015 for type A foam.

2.2.3 Lining. The lining material shall be nylon taffeta; fully heat set at a Minimum temperature

of 4000 F (2040C) The shade shall be black. The yarn shall be continuous filament, semi dull or

equal for the warp and filling and shall conform to the physical requirements of Table III when

tested as specified.

2.2.4 Fusible Interlining. The fusible interlining utilized to impart stiffness to flaps and closures

shall be of a type suitable for the intended end use.

2.2.5 Fleece lining. The fleece lining for the chest pockets shall be made of 100% polyester, 6.4

oz/yd2, 32 gauge knit fabric.

5

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business