A-A-55278A

8/ In the determination of presence of labile sulfur in textile materials with lead acetate, two

1.50 + 0.01 gram samples from each material submitted for evaluation shall be tested. Each of

the two samples shall be cut into very small pieces and placed into separate test tubes. The

samples shall be submersed in a stannous chloride solution that contains 100 grams of stannous

chloride crystals ACS in 100 milliliters of hydrochloric acid ACS (35 percent concentration) and

50 milliliters of distilled water. A filter paper wet out with a 5.0 percent lead acetate solution

shall be placed over top of the test tube. The lead acetate solution contains 5.0 grams of lead

acetate CP reagent grade and enough distilled water to make up a 100 milliliters solution; if the

solution is not clear, add a few drops (one at a time) of glacial acetic acid until the solution is

clear. The test tube containing the textile sample, stannous chloride and wet filter paper shall be

heated over a low flame until the solution is boiling. The solution should not be heated for more

than 15 seconds. A brown to black stain on the filter paper should be evaluated as follows:

Free the filter paper shows no discoloration or staining of any kind.

Slight The filter paper shows a light tan to light brown discoloration stain.

Moderate The filter paper shows a dark brown discoloration stain.

Severe The filter paper shows a black color stain.

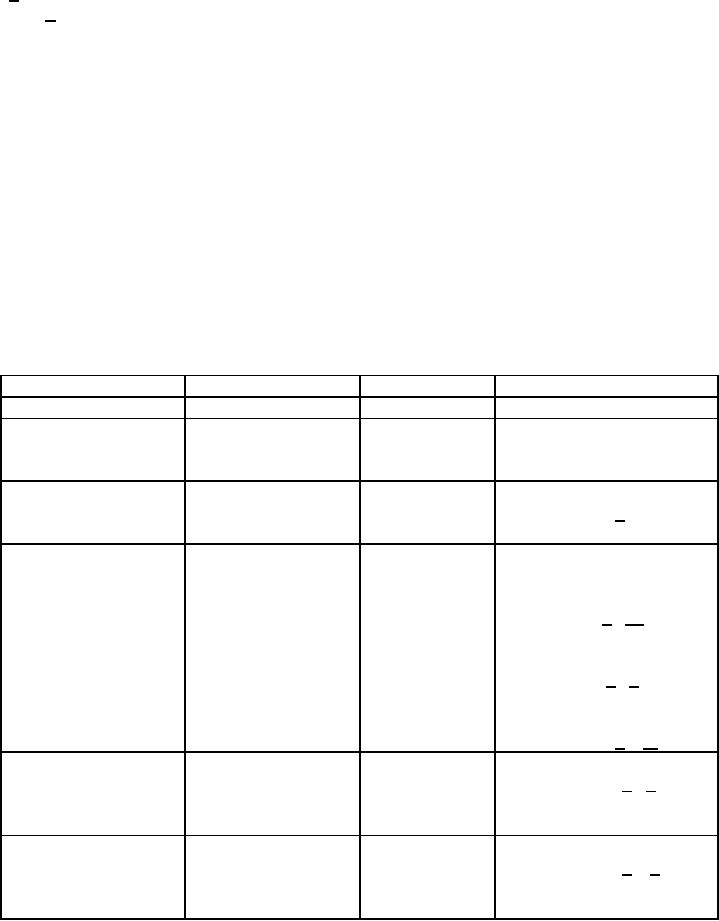

Table II - Coated Cloth Physical Requirements

Characteristic

Minimum

Maximum

Test Method

Weight, oz./yd.2

7.0

9.0

ASTM D3776 Opt. 7

Breaking strength, lbs.

Warp

225

ASTM D5034

Filling

210

Tear strength, grams

ASTM D1424 1/

4500

Warp

3500

Filling

-

Hydrostatic

Resistance, lbs./in2

ASTM D751 2/ 12/

100

Initial

80

AATCC-96 VI A

After 5 launderings

ASTM D751 2/ 8/

80

After 40 hours

AATCC-111A opt. 4

weatherometer

ASTM D751 2/ 8/

Flex stiffness, inch-

lbs. x 10-4 at 70oF

ASTM-D-1388 3/ 4/

9.0

-

Warp

7

-

Filling

Flex stiffness, inch-

Lbs x 10-4 at -20oF

ASTM-D-1388 3/ 5/

25

-

Warp

25

-

Filling

4

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business