A-A-55278A

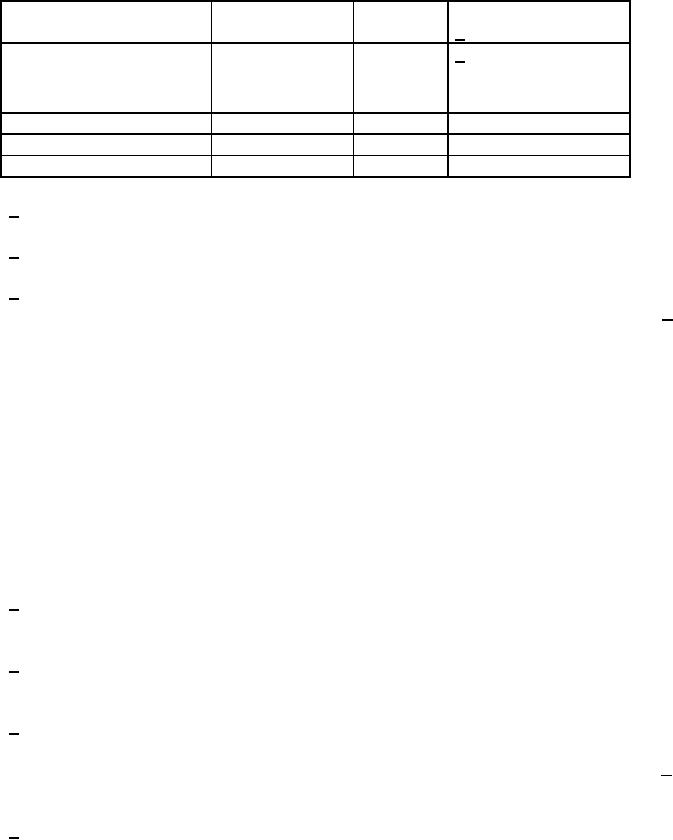

Table I - Uncoated Cloth Physical Requirements (continued)

Crocking, Munsell Value

-

8.5

AATCC 16 option A

7/

No more labile

Sulfur content

8/

sulfur than shown

by the standard

sample

PH

5.0

8.5

AATCC-81

Copper content

-

0.003%

ASTM-E-1452

Manganese Content

-

0.0015%

ASTM-E-1452

1/ One determination per sample unit and the results reported as "pass" or "fail".

2/ A certificate of compliance will be acceptable for this requirement.

3/ The test specimen shall consist of a square of cloth at least 12 by 12 inches, marked off with a

square 10 by 10 inches. The test specimen shall be placed in an oven maintained at 280oF +2o

for a period of 2 hours. The specimen shall be removed from the oven and conditioned under

standard atmospheric conditions. The specimen shall then be measured for dimensional changes.

The measurements shall be made at least 1 inch from the edge of the square and at the center of

the square in the warp and filling direction. The specimen shall then be visually compared with

the original unheated fabric for distortion, or puckering. One specimen shall be tested from each

sample unit. The dimensional change of the sample unit in the warp and filling direction shall be

the average of the specimens tested from each direction, respectively, and shall be reported

separately to the nearest 0.1 percent. Distortion and puckering shall be reported as "pass" or

"fail".

NOTE: When cutting the samples, make certain the twill line goes from the lower left to the

upper right in a 45 degree angle.

4/ One determination per sample unit and the dimensional change reported to the nearest 0.1

percent.

5/ Samples shall be conditioned as directed in "D1776 Practice for Conditioning Textiles for

Testing" prior to testing.

6/ The specimens must be dried after each of the three laundering cycles. The soap solution shall

contain 0.5 percent by weight, P-D-245, Detergent, Laundry, and Hand Dishwashing (Granular)

Type II, in water hardness not over 50 parts per million. The specimen weight shall be 4.0 +0.5

grams and the rotating time shall be 30 minutes with ten stainless steel balls in each cylinder.

7/ When a color change equal to Step 4 on the Gray Scale is evident in either the evaluation

sample or the standard sample, exposure shall be continued for an additional number of hours

equal to the number of hours at which the color change was apparent. Specimens which do not

show a color change until 80 AFU's shall be returned to the machine for a total exposure period

not to exceed 140 hours.

3

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business