A-A-55294A

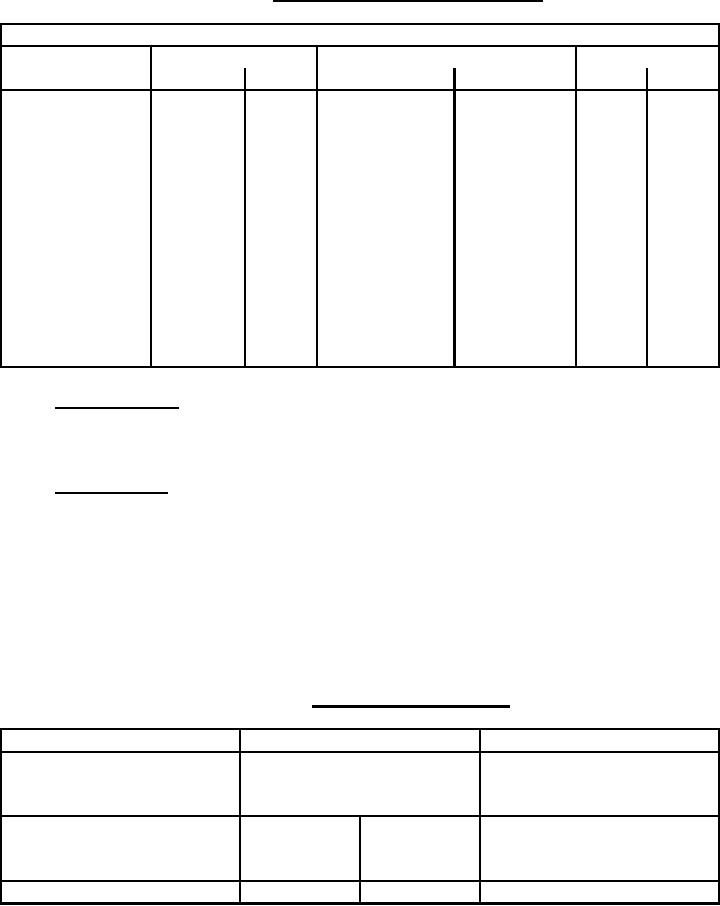

TABLE II. Spectral reflectance requirements

Reflectance values (percent)

Wavelength

Light Green 354

Dark Green 355 and Brown 356

Black 357

Nanometer (nm.)

Min

Max.

Min.

Max.

Min.

Max.

600

8

18

3

9

--

10

620

8

18

3

9

--

10

660

8

18

3

12

--

10

680

10

22

3

14

--

10

700

18

33

5

18

--

10

720

22

45

7

20

--

10

740

30

55

12

28

--

10

760

35

65

18

36

--

10

780

40

75

26

44

--

10

800

45

80

34

52

--

10

820

50

86

42

60

--

10

840

55

88

50

68

--

10

860

60

90

56

74

--

10

3.2.2 Visor interlining. The visor interlining shall be a plastic high density polyethylene

material weighing 12.0 to 14.5 grams per visor, having a thickness of 0.083 to 0.089 inch, and

40 to 60 percent stiffness when tested in accordance with ASTM-D-747.

3.2.3 Cap interlining. The inside of the center front of the cap shall be stabilized with a

square cut piece of natural white, plain weave, multifilament polyester or nonwoven

interlining made from 100 percent polyester continuous filament fibers that are randomly

arranged and bonded at the filament junctions or from a blend of staple nylon and staple

rayon fibers, or a blend of polyester and nylon or rayon staple bound with a suitable acrylic

binder. The contractor shall submit a certificate of compliance to ensure that the fiber

content requirement has been met. The stabilizer cloth shall be cut 3 inches wide, and the

length shall extend from the top crown joining seam to the visor joining seam. The interlining

shall conform to the requirements specified in Table III.

TABLE III. Interlining requirements

Characteristic

Requirement

Test method

Weight(oz./sq. yd., min.)

ASTM-D-1117, Section 17

3.4

Non-woven

ASTM-D-3776

3.3

Woven

Filling

Warp

Breaking strength (lbs., min.)

80

ASTM-D-1117, Section 7

100

Non-woven

ASTM-D-1682, Section 16

190

150

Woven

Warp stiffness (in./lbs.)

0.0030(min.)

0.0120(max.) ASTM-D-747

4

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business