A-A-55294A

3. SALIENT CHARACTERISTICS

3.1 Description. The cap shall be a visor style, having a circular top crown, and a one piece,

self-lined side crown with a center back seam. The outside crown band shall be topstitched

around the bottom of the side crown. The crown seam shall be reinforced with a bias cut strip

of self fabric between inner and outer plies. The cap shall have six vents which are made by

metal eyelets uniformly positioned around the sides and back of the cap. The visor shall be

quilted with six rows of evenly spaced parallel lockstitching, and the inner edge of the visor

interlining shall abut the bottom of the topstitched side crown band. The under visor cover

shall overlap the top of the visor 1/4 inch and stitch through plies and interlining 3/16 to 1/4

inch from the outer edge. The cap shall be topstitched around the top of the side crown

(without catching inner lining), the top and bottom of the under visor cover, and along the

center back seam.

3.1.1 Seams and stitching. All seams and stitching shall be 10 to 14 stitches per inch except

for the stitching through the visor and the stitches for seaming the visor cover together along

the inner edge of the visor interlining (not through the interlining). These shall be 6 to 8

stitches per inch. Top stitching shall be performed using a 300 series lockstitch. The gage of

stitching for all topstitching shall be 1/8 to 3/16 inch.

3.2 Material.

3.2.1 Basic material. The cloth shall be woodland camouflage printed, water-repellent-

treated ripstop poplin. The ribs shall be formed by having every twenty-fourth warp end

contain two ends weaving as one and every thirteenth filling contain two picks weaving as

one. The cloth shall be a blend of 50 + 5 percent nylon, 1 percent static dissapative fiber,

with the remaining percentage combed cotton. The warp yarn shall be 2-ply and the filling

yarn shall be 2-ply or singles. As an alternate to the basic material, the cloth for the side

crown lining and the crown seam reinforcement strip shall be ground shade cloth, printed

seconds cloth, or dyed seconds cloth. The color shall be a Woodland Camouflage Pattern

(Light Green 354, Dark Green 355, Brown 356, and Black 357). All colors of the finished

cloth shall match the standard sample when viewed under filtered tungsten lamps that

approximate artificial daylight and that have a correlated temperature of 7500 + 200 K, with

illumination of 100 + 20 foot candles, and shall be a good match to the standard sample under

incandescent lamplight at 2300 + 200 K. The cap shall conform to the requirements specified

in Table I.

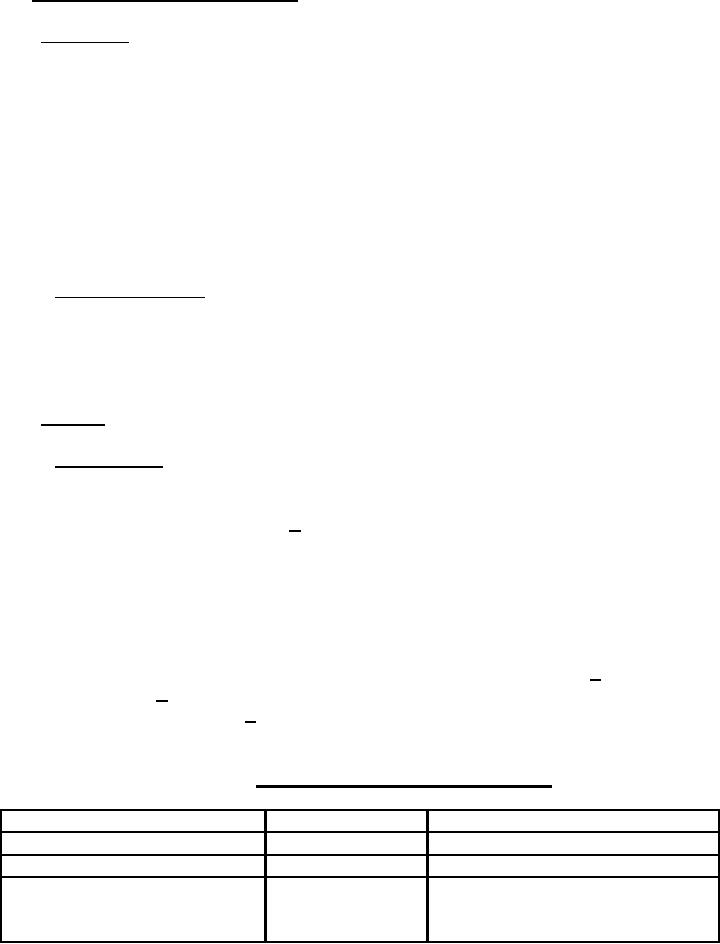

TABLE I. Basic material physical requirements

Characteristic

Requirement

Test method

Weave

Plain

Visual

Weight, oz./sq.yd.

6.0 - 7.0

ASTM-D-3776, Option C

Yarns per inch (min.)

104

ASTM-D-3775

Warp

ASTM-D-3775

Filling

52

2

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business