A-A-55294A

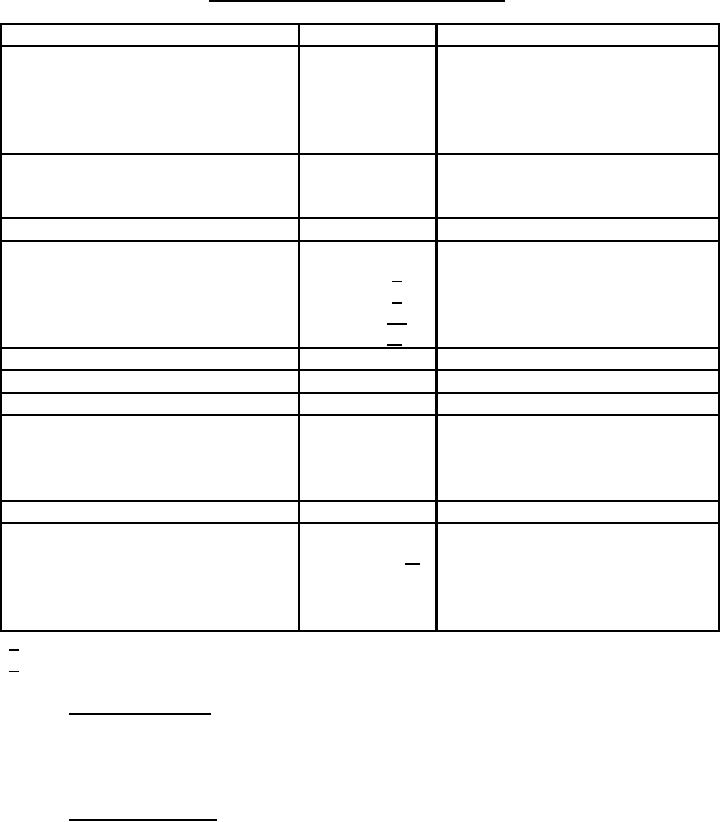

TABLE I. Basic material physical requirements - continued

Characteristic

Requirement

Test method

Breaking strength, (lbs., min.)

200

ASTM-D-5034, Option G-T or G-

Warp

E

Filling

90

ASTM-D-5034, Option G-T or G-

E

Tearing strength, (lbs., min.)

Warp

7.0

ASTM-D-1424

Filling

5.0

ASTM-D-1424

3

2

Air permeability, (ft. /min./ft. ), max.

10.0

ASTM-D-737

Colorfastness to:

"good" 1/

Laundering

AATCC 61, 3A

Perspiration

AATCC 15

"good" 1/

Crocking

AATCC 8

"good" 1/

Light

AATCC 16, Option A

"good" 1/

Spectral reflectance, (nanometers)

600 - 860

3.2.1.2

Non-fibrous material, (%, max.)

2.0

ASTM -D-629, Section 9

pH

5.0 - 8.5

ASTM-D-2165

Dimensional stability

(percentage, max.)

Warp

3.5

AATCC 96, Option 1C & D

Filling

3.5

AATCC 96, Option 1C & D

Seam efficiency, (% max.)

80

ASTM-D-1683

Water repellency

Dynamic absorption

AATCC 70

Lot average 2/

25

Initial

25

After 15 launderings

90, 90, 80

AATCC 118

Spray rating (3 determinations)

1/ or equal to standard sample

2/ No individual specimen shall exceed 30.

3.2.1.1 Electrostatic decay. The finished cloth, when charged toward +5000 volts and -5000

volts, reads a minimum level of +4000 and -4000 volts, respectively, and shall dissipate 90

percent of the charge in one-half second or less after five launderings on the face side. The

test shall be conducted in accordance with AATCC 96 and ASTM-D-4258.

3.2.1.2 Spectral reflectance. The spectral reflectance values for each color in the Woodland

Camouflage printed cloth shall conform to the requirements specified in Table II.

3

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business