A-A-55063A

4--Blocking. Cloth surfaces separate with difficulty or coating is removed during

separation.

3/ The 4-1/2 inch diameter test area shall show no leakage. Leakage is defined as the

appearance of water at three different places in the 4-1/2 inch diameter test area.

4/ The hydrostatic head shall be raised to a height of 20 inches for a period of 1 hour and then

examined for leakage.

5/ Extent of leakage shall be not more than 5 milliliters of water.

6/ An area approximately 2 - inches by 8 - inches extended along the center line of the

specimen shall be abraded by means of a 2- inch square of 1/0 garnet paper. The garnet paper

shall be uniformly loaded to 8.0 (± 0.1) ounces. The specimen shall be laid on a smooth level

surface with the heavily coated side up and abraded as described by moving the loaded garnet

paper five times in each direction. The specimen shall be turned over and abraded on the other

side (i.e. The specimen is abraded in a North-south direction on one side and an east-west

direction on the other side). The abraded specimen shall be tested with the abraded area in the

center of the 4-1/2 inch diameter test area. The hydrostatic head shall be raised to a height of

20 - inches for a period of 1 hour. A leakage of more than 5 milliliters of water by the end of

the test period shall be reported as a test failure.

3.2.1.1.1 Coating compound. The coating compound shall be chloroprene rubber or

polyisobutylene rubber suitably compounded plasticized with phthalate or phosphate ester

plasticizers, and pigmented black when tested as specified in ASTM D 297. Natural rubber,

synthetic rubber other than chloroprene rubber, or reclaimed rubber shall not be used.

3.2.1.2 Dusting powder. The dusting powder for application to the coated cloth shall be a

whiting, finely divided non-toxic mineral material of ground potassium aluminum silicate (see

7.5).

3.2.2 Tape/webbing (nylon or polyester). The tape/webbing shall be 3/4 (-1/32, + 1/16) inch

wide, and sufficiently lightweight and flexible for tying when the apron is donned. The fiber

content shall be nylon or polyester when tested in accordance with AATCC 20. The

tape/webbing shall meet the requirements of Table III when tested in accordance with the

methods provided therein. The apron shall have two (2) tapes/webbings for the waist cut to 24

(± 1/2) inches in length, and one (1) tape/webbing cut to 30 (± 1/2) inches for the neck strap.

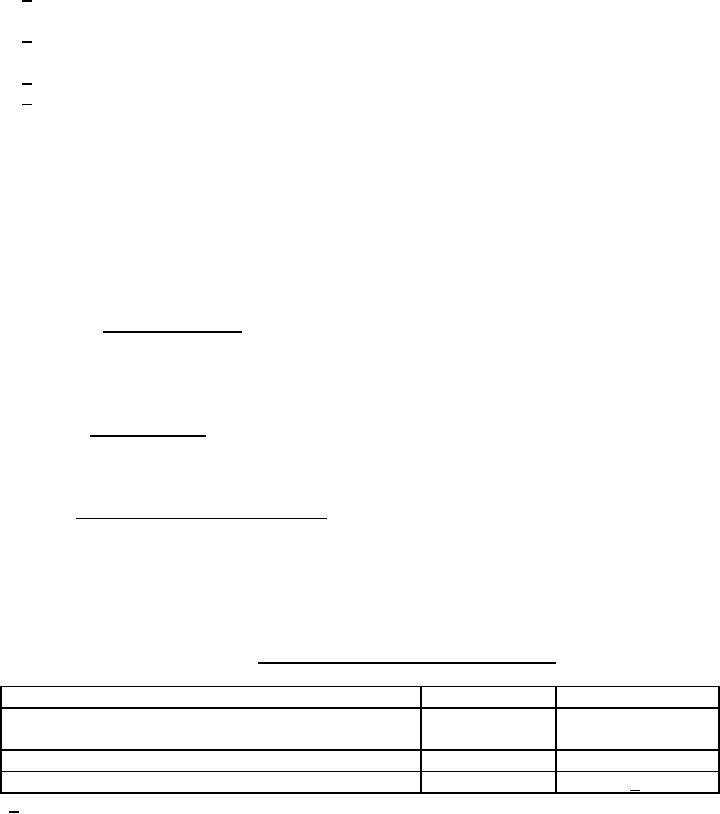

TABLE III. Tape/webbing performance requirements

Characteristic

Requirement

Test Method

Water Repellency

Dynamic absorption, percent, initial only (maximum)

40

AATCC - 70

pH

5.5 - 8.5

AATCC 81

Labile sulfur

None present

1/

1/ The presence of labile sulfur test method shall be as follows unless otherwise specified in the

contract or solicitation (see 7.6): In the determination of presence of labile sulfur in textile

materials with lead acetate, two 1.50 (± 0.01) gram samples from each material submitted for

evaluation shall be tested. Each of the two samples shall be cut into very small pieces and placed

into separate test tubes. The samples shall be submersed in a stannous chloride solution that

3

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business