A-A-55277A

3. SALIENT CHARACTERISTICS

3.1 Description. The fleece sweatshirt, Air Force Class 1 (see Figure 1), Army Class 2 (see

Figure 3) shall have long sleeves and have a 1 X 1 rib knit crew neck collar of double thickness.

The collar shall finish 1-1/8 (+/- 1/8) inches wide and shall be coverstitched. The wales shall run

in the length wise direction of the finished item. The sweatshirt shall have sewn on cuffs of the

same material as collar in double thickness. The cuffs shall finish 2-1/2 (+/-1/4) inches long and

3-3/4 (+/- 1/4) wide when measured across center of cuff. The cuff seam may be coverstitched.

The bottom of the sweatshirt shall have a waistband of the same material as the collar in double

thickness. The waistband shall finish 2-1/2 (+/- 1/4) inches wide and may have seam

coverstitched. The sweatshirt shall have the inscription "AIR FORCE" for Class 1 (see Figure 1)

"ARMY" Class 2 (see Figure 3), screen printed across the front in accordance with Figures 2 and

4 and positioned for each size in accordance with Table I.

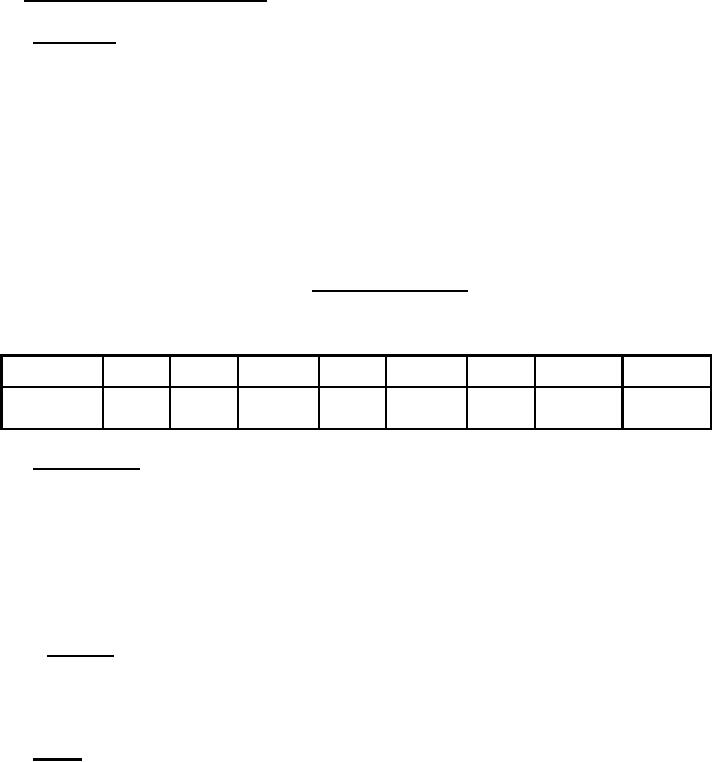

TABLE I. Screen Print Location

(below bottom of neckband to top

of lettering in inches)

Size

X-Sm

Small

Medium

Large

X-Large

XX-L

XXX-L

Tolerance

Placement

of lettering

3

3-/12

4

4-1/2

5

5-1/2

6

+/- 1/2

3.2 Basic material. The sweatshirts shall be fabricated from Jersey knit type fleece fabric having

55 (+/- 5) percent cotton with the remaining percentage polyester. The fleece fabric shall weigh

9.0 (+/- 0.5) ounces per square yard when tested in accordance with ASTM-D-3376, have a

minimum of 20 wales per inch and a minimum of 27 courses per inch when tested in accordance

with ASTM-D-3887. The material shall have a minimum bursting strength of 75 pounds when

tested in accordance with ASTM-D-3787 and shall not shrink or elongate more than 10 percent

when tested in accordance with AATCC Method 150 using normal machine cycle. The material

shall match the standard samples (see 7.3).

3.2.1 Matching. The color of the finished cloth shall match the standard sample when viewed

under filtered tungsten lamps that approximate artificial daylight and having a correlated color

temperature of 7500 (+/- 200K), with illumination of 100 (+/- 20) foot candles, and shall be a

good match to the standard sample under incandescent lamplight at 2300 (+/- 200K).

3.4 Thread. The thread for seaming and stitching shall be 2-ply cotton covered polyester or

spun polyester. The color shall be light gray, or a good match to the basic material and show

good colorfastness to laundering. The thread shall have a breaking strength of 1.8 lbs minimum

and shall be tested in accordance with ASTM-D-2256.

2

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business