A-A-55276A

3. SALIENT CHARACTERISTICS

3.1 Description. The fleece sweatpants (see Figures 1, Air Force and Figure 4, Army) shall have a 1-

1/4 inch wide covered elastic waistband with 4 rows of stitching and a concealed drawcord and a

straight cut bar type buttonhole with ends securely tacked on inside of center front of the waistband.

The sweatpants shall have two side pockets, opening shall be 6 (+/- 1/4) inches with a depth of 7 (+/-

1/4) inches. The top and bottom of pocket opening shall be securely tacked. The sweatpants shall

have 1/4 inch wide covered elastic at the cuff of each leg opening. The ARMY sweatpants shall have

lettering "ARMY" (see Figure 3) screen-printed down left leg. The lettering for Class 2 sweatpants

shall be Black and beginning 12-1/2 inches below top of waistband centered between seams (see

Figure 3). The AIR FORCE sweatpants shall have the logo (see Figure 2) printed on the left front

centered and positioned as outlined in Table 1. The screen print shall match Navy blue shade 35048 of

FED- STD-595, for the Class 1.

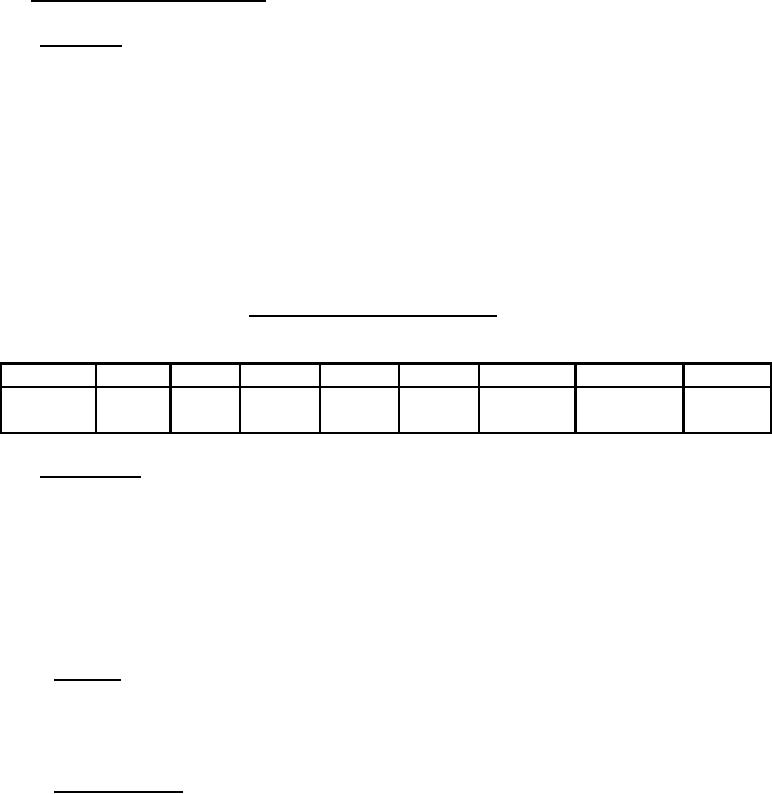

Table 1 Screen Print Location For Air Force

(below bottom of waistband, inches)

Size

x-Small

Small

Medium

Large

X-large

XX-Large

XXX-Large

Tolerance

Placement

of logo

3

3-1/2

4

4-1/2

5

5-1/2

6

+/- 1/2

3.2 Basic materials. The sweatpant shall be fabricated from Jersey Knit type fleece fabric having 55

(+/- 5) percent cotton with the remaining percentage polyester. The fleece fabric shall weigh 9.0 (+/-

0.5) ounces per square yard when tested in accordance with ASTM-D-3376, and have a minimum of

20 wales per inch and a minimum of 27 courses per inch when tested in accordance with ASTM-D-

3887. The material shall have a minimum bursting strength of 75 pounds when tested in accordance

with ASTM-D-3787 and shall not shrink or elongate more than 10 percent when tested in accordance

with AATCC Method 150 using normal machine cycle. The material shall match the standard sample

for shade (see 7.3).

3.2.1 Matching. The color of the finished cloth shall match the standard sample when viewed under

filtered tungsten lamps that approximate artificial daylight and having a correlated color temperature of

7500 (+/- 200K), with illumination of 100 (+/- 20) foot candles, and shall be a good match to the

standard sample under incandescent lamplight at 2300 (+/- 200K).

3.2.2 Pocketing material. The material for the pocketing may be fleece or Jersey material. When

fleece is used it shall match the basic material. The Jersey material shall have 55 (+/- 5) percent cotton

and the remaining percentage polyester. The material shall weigh 5.5 (+/- 0.5) ounces per square yard,

have a minimum of 30 wales per inch and have a minimum of 45 courses per inch when tested in

accordance with ASTMD-3887. The Jersey material shall have a minimum bursting strength of 75

pounds when tested in accordance with ASTM-D-3787 and shall not shrink or elongate more than 10

2

2

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business